-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Grinding Mill

Direct deal Quality Assurance Quick response Service worry free

Production capacity:2-150(t/h)

Feed particle size:<10, max 15mm

Applicable materials: Artificial granite, plastic masterbatch, papermaking, coatings, PVC, wire and cable, rubber, pigments, ink non-woven fabrics and other industries, Large-scale ultrafine grinding of various non-metallic minerals with Mohs hardness below 7 and moisture content less than 6% such as calcite, limestone, marble, heavy calcium, quicklime, talc,barite, dolomite, and kaolin .

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

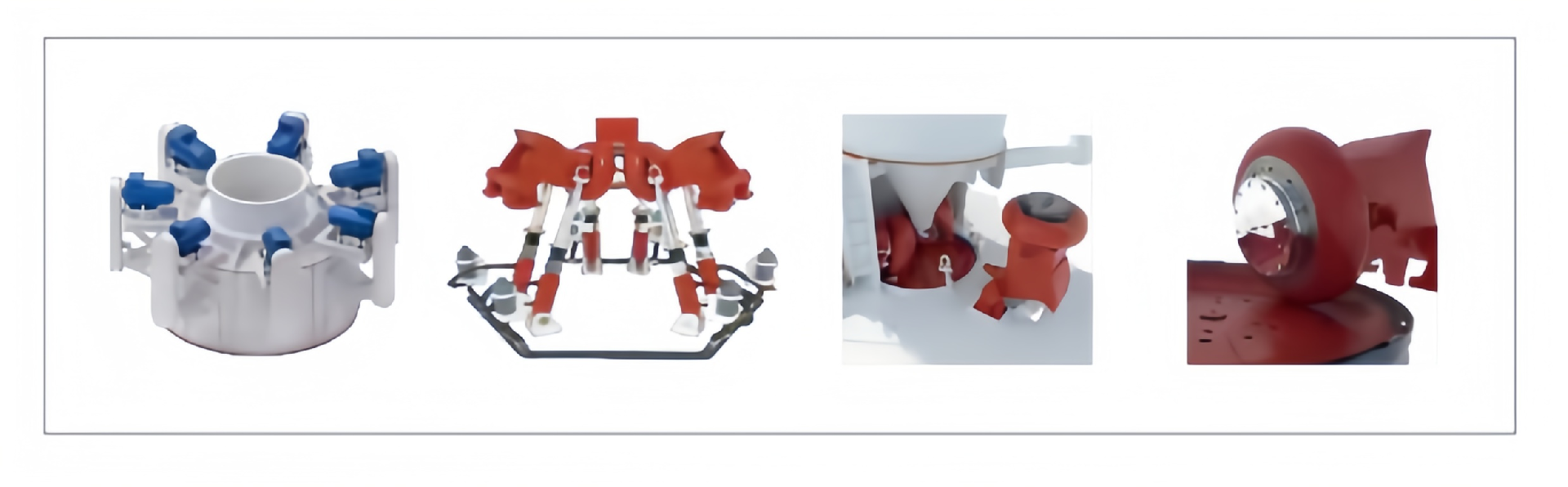

The LUM ultrafine vertical mill is a mill independently developed and designed by Santak Machinery based on its many years of experience in mill production. It adopts Taiwan's latest grinding roller technology and German powder selection technology. It integrates ultrafine powder grinding, grading and conveying, making it the preferred product in the ultrafine powder grinding industry.

Professional ultra-fine vertical mill

LVM ultra-fine vertical mill professional ultra-fine vertical mill products, introducing advanced technology from Germany, Japan and Taiwan .

Environmentally-friendly

LVM ultra-fine vertical mill the entire system runs in negative pressure and dust-free operation .

High separation efficiency

LVM ultra-fine vertical mill the powder classifier adopts a multi-wheel air-flow classifier, which has precise particle size control and high efficiency, and can produce a wide range of finished products. The cumulative percentage content below 2um can reach D97=4-45pm, and the specific surface area is 21000m2/g。

High quality of finished powder

LVM ultra-fine vertical mill the iron content in the finished powder is very small, when the white material is ground, the whiteness of the product is high,and the particle size distribution of the finished product is narrow, the content of 2um fine powder is adjustable and controllable, and the shape of a single particle is good.

Low noise and less abrasion

LVM ultra-fine vertical mill equipped with a mechanical limit device and an electronic limit device to prevent direct contact between the roller and the grinding disc liner, the ultra-fine vertical mill avoids destructive impact and severe vibration. Both the grinding roller and liner are made of high-quality wear-resistant materials, so there is less wear and long service life .

Specially designed grinding curve

LVM ultra-fine vertical mill the specially designed grinding curve of the roller and liner makes it easier to form a material layer than ordinary vertical mills, and grind to th required material fineness at one time, which greatly improves the grinding efficiency.

Intelligent automatic control system

LVM ultra-fine vertical mill the ultra-fine vertical mill adopts the PLC/DCS automatic control of the grinding roller pressure control method,which can accurately control the grinding pressure without manual operation. It can also add grinding aids under automatic computer control for grinding treatment, realize remote control, and easy operation .

The material falls to the center of the grinding disc of the LVM ultra-fine vertical mill through the spiral feeder. Driven by the main motor, the reducer drives the grinding disc to rotate, forming centrifugal force, forcing the material to move to the edge of the grinding disc. When passing through the grinding area between the grinding roller and the grinding disc, the large pieces of material are directly crushed by the pressure of the grinding roller, and the fine materials form a layer of materials crushed against each other.

The crushed material after grinding continues to move to the edge of the grinding disc until it is carried away by the air flow and enters the powder selector. Under the action of the powder selector blades, the coarse particles that do not meet the fineness standard fall on the grinding disc and continue to be ground. The fine powder that meets the fineness standard enters the powder collector and is the finished product.

For iron blocks and other debris in the material, when they move to the edge of the grinding disc, due to their large specific gravity, they will fall into the lower cavity of the mill, and then be sent to the discharge port by the scraper installed at the bottom of the grinding disc, and finally discharged from the mill.

| Specifications | LVM15-3X | LVM16-3X | LVM17-3X |

| Main Mill Power (KW) | 220-280 | 315-400 | 355 - 450 |

| Blower Power (KW) | 180-200 | 250-280 | 325 - 355 |

| Multiple Separator Powder x Q'ty | 15KW x6 | 22KW x6 | 22KW x 8 |

| Input Size (mm) D90 | <10, max 15mm | <10, max 15mm | <10, max 15mm |

| Input Moisture | <3% | <3% | <3% |

| Q'ty or Rollers (pcs) | 3 | 3 | 3 |

| Capacity with D30, 2μm ( t/h) | 9-12 | 12-16 | 14-18 |

| Capacity with D45, 2μm ( t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Capacity with D60, 2μm (t/h) | 3-4 | / | / |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.