What is jaw crusher:

Jaw crusher is the most commonly used type of crusher in mines and ore processing plants. It can crush various types of ores and river pebbles. It is the primary crusher used in mines and ore processing plants, also known as stone coarse crusher.

Jaw crushers are widely used in various industries such as mining, construction and recycling because they can crush materials of various sizes and compositions. In this article, we will explore the various application industries and advantages of jaw crushers.

What are the benefits of jaw crusher?

1. Large crushing ratio:

The structural design of jaw crusher machine enables it to achieve a large crushing ratio

2. Adapt to various material hardness:

Whether it is ore with higher hardness or limestone with relatively lower hardness, jaw crusher machine can effectively crush it.

3. High production efficiency:

It is reflected in the dead zone-free design and good continuous working performance.

4. Stable operation characteristics are reflected in flywheel energy storage and sturdy frame.

5. Simple and easy to understand structure:

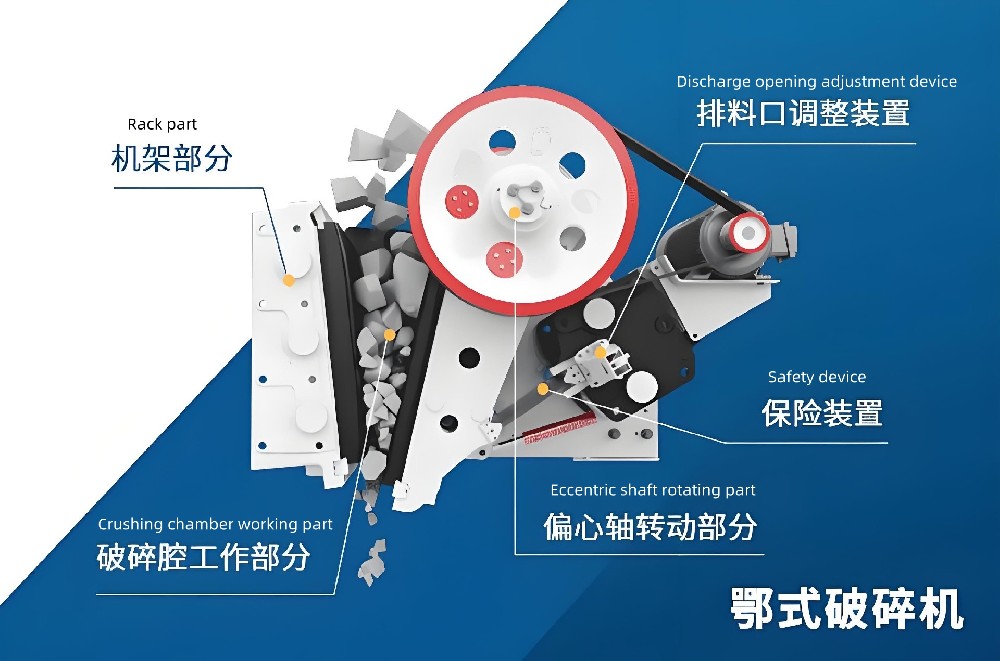

The overall structure of jaw crusher is relatively simple, mainly composed of frame, jaw plate, eccentric shaft, flywheel and other components

6. Easy maintenance:

Due to the reasonable structural design, the maintenance of jaw crusher machine is relatively easy

7. Low transportation cost:

From the perspective of equipment procurement cost, the price of jaw crusher machine is relatively low compared to some other complex crushing equipment, such as cone crusher and impact crusher. The energy consumption of jaw crusher during operation is relatively reasonable.

What are the application areas of jaw crusher?

1: Mining industry:

Metallic ores include different types of metal ores, such as iron ore and chrome ore, which are very hard. Jaw crushers use strong pressure to crush large pieces of iron ore into smaller pieces. This creates the right size for subsequent grinding and processing.

The same process is also used for non-ferrous metal ores, such as copper, lead, and zinc ores. After these ores are mined, they first enter the jaw crusher for coarse crushing to make them suitable for the next processing size.

Non-metallic ores include limestone, gypsum, quartz, etc. Limestone is the main source of building materials and chemicals. Jaw crushers can easily break up large pieces of stone and crush them into sizes suitable for further processing.

2: Construction industry

Sand and gravel production:

Jaw crusher is a key equipment in the process of machine-made sand and gravel production. With the increasing scarcity of natural sand and gravel resources, the production of machine-made sand and gravel is becoming more and more important. Jaw crusher can coarsely crush raw materials such as mountain rocks and river pebbles.

Construction waste treatment:

Jaw crusher plays an important role in the recycling of construction waste. There are a lot of concrete blocks, bricks, etc. in construction waste. Jaw crushers can crush these construction wastes and crush concrete blocks into recycled aggregates, which can be made into recycled concrete, bricks and other building materials.

3: Metallurgical industry

Steel metallurgy:

In steel production, jaw crushers are the key to front-end ore processing. The mined iron ore is coarsely crushed, which is conducive to subsequent beneficiation, sintering and other processes. In the beneficiation process, the appropriate coarse crushing particle size is extremely important for the magnetic separation and flotation separation of iron concentrate, which can provide high-quality raw materials for blast furnace ironmaking.

In non-ferrous metal metallurgy, copper, aluminum, zinc and other ore raw materials also need to be coarsely crushed by jaw crushers. For example, copper ore is coarsely crushed and then goes through grinding, flotation and other processes to obtain copper concentrate, which is then smelted into copper metal products.

4. Transportation construction industry

Highway construction:

In highway projects, roadbeds and subbases require a lot of crushed stone. Jaw crushers can crush mined stones into crushed stones of appropriate particle size. After screening and grading, these crushed stones are mixed with materials such as cement and asphalt to form a stable roadbed structure and enhance the bearing capacity of the road.

Railway construction:

Jaw crushers are also used to produce railway ballast. Ballast is generally composed of crushed stone and is used to lay railway tracks to provide support, drainage and cushioning for the tracks. Jaw crushers can crush stones and produce crushed stones that meet railway ballast standards.

Overall:

jaw crushers are important tools in various industries such as mining, construction, metallurgy and transportation construction. They are highly efficient and can handle large amounts of material, making them essential equipment in many industrial environments.