-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Mobile Crushing Plant

Direct deal Quality Assurance Quick response Service worry free

Production capacity:120-640t/h

Feed particle size:≤50mm

Applicable materials:Limestone, granite, basalt, diabase, andesite, ore tailings, construction waste, etc.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

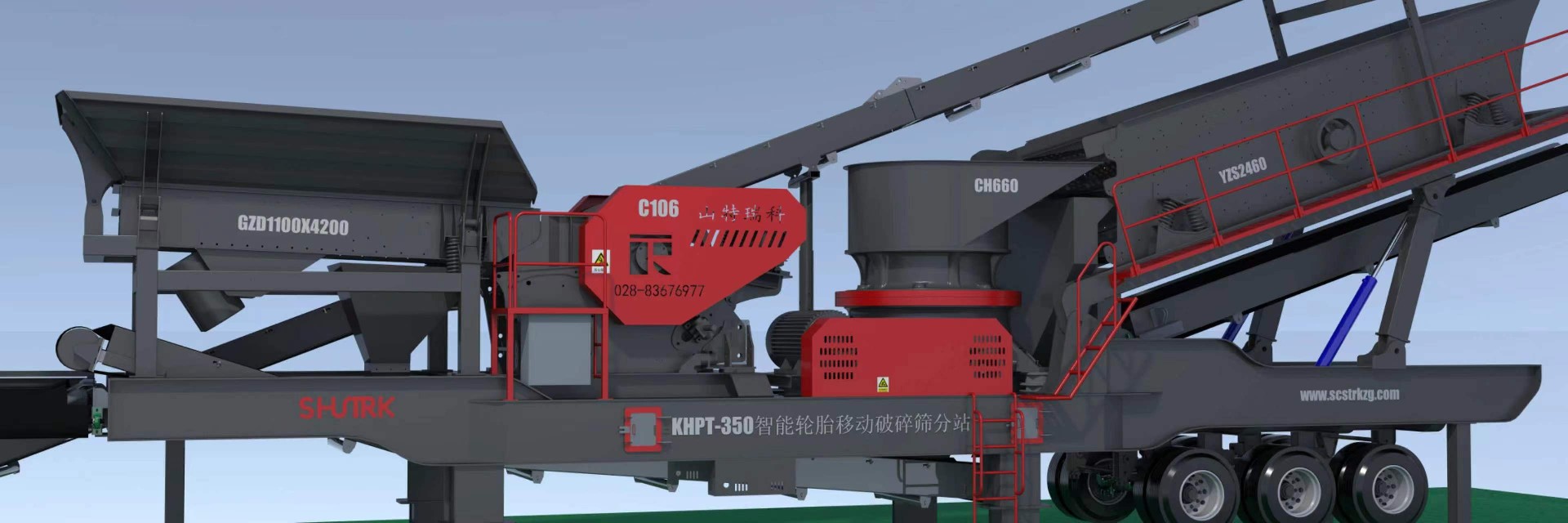

The K6 series tire mobile crushing plant has 18 models, which can be used to process hard rock (conventional granular type, fine crushing), soft rock (conventional granular type, sand making) and construction waste. The K3 series mobile crushing plant has 5 frame types and is equipped with 24 standard portable equipment modules. The main features of the mobile crushing plant are: fast installation and production; modular installation is simple, flexible movement, and maximum standardization and generalization are achieved.

1. Mobile crushing plant is highly flexible:

Whether it is tire-type or crawler-type, it is easy to move, has good mobility for different construction sites, saves disassembly time and cost, etc., and is suitable for temporary and scattered sites such as construction sites, small mines, and urban demolition.

2. Mobile crushing plant has strong site adaptability:

It can adapt to various terrains and conditions, such as rugged roads, narrow spaces, muddy ground, etc. The crawler type is more stable and has better passability.

3. Mobile crushing plant has integrated design and saves costs:

The integrated unit form is easy to install, reducing installation time and labor costs. The transportation cost is low, the materials can be crushed on site, and some can directly transport the crushed materials to improve efficiency.

4. Mobile crushing plant has flexible combination and strong adaptability:

There are various process configurations such as "crushing first and then screening" or "crushing first and then screening", which can form a multi-stage crushing and screening system. The main machine can be switched freely according to the characteristics of the material, and one machine can be used for multiple purposes.

Reliable performance and easy maintenance. The main machine adopts high-strength and other optimized designs, and the operation is stable. Centralized lubrication system, unified maintenance tool box, integrated unit, easy maintenance and repair.

5. Mobile crushing plant is environmentally friendly:

The crushing process can be closed to control dust, and some are equipped with advanced dust removal equipment. Advanced sound insulation technology and materials reduce noise pollution.

Tire-type mobile crushinglant: All parts are onboard, including a solid frame, crusher (such as jaw crusher, cone crusher, impact crusher, etc.), vibrating screen, conveyor, motor and control box.

During operation, the material is transported to the crusher through an external conveyor, and the crusher performs preliminary crushing on the material. For example, the jaw crusher performs coarse crushing on the material through the mutual squeezing of the moving jaw plate and the static jaw plate. The material that has been initially crushed is then screened through a vibrating screen to form a closed-circuit system to achieve cyclic crushing of the material, and the finished material that meets the particle size requirements is output by a belt conveyor.

Mode | Feeding and | Crushing | Belt conveyor | Hopper volume(㎥) | Max.feed size(mm) | Transportation dimension(mm) |

K6T70-4 | GZD0936 YZ51548 | PE500X750 | B650×10.5m | 3 | 425 | 15150×2800×4500 |

K6T100-4 | GZD0936 | C6X80 | B800x10.5m | 4 | 430 | 15500×2650×4000 |

K6T150-4 | GZD0936 | C6X80 | B800×10.5m | 4 | 430 | 15500×2650×4000 |

K6E760-1 | GZD1245 | PEW760 | B1200×10m | 6.5 | 630 | 12800×2800×4200 |

K6C100-1 | GZD1245 | C6X100 | 31200×10m | 6.5 | 630 | 12800×2800×4100 |

K6C110-1 | GZD1245 | C6X110 | B1200×10m | 6.5 | 720 | 12800×2800×4100 |

K6CI1213-1C | GZD1245 | CI5X1213 | B1200×10m | 6.5 | 530 | 12800×2800×4100 |

K6F1315-1C | GZD1245 | CI5X1315 | B1200×10m | 6.5 | 600 | 12800×2800×4100 |

K6H300-1 | -- | HPT300 | B1200×6.3m | 4.5 | 180 | 12650×2800×4000 |

K6CI1213-1 | -- | C15X1213 | B1200×6.3m | 4.5 | 300 | 12650×2800×4000 |

K6CI1315-1 | -- | C15X1315 | B1200×6.3m | 4.5 | 300 | 12650×2800×4000 |

K6V9026-1 | -- | VSI6X9026 | B1200×6.3m | 4.5 | 35 | 12650×2800×4000 |

K6H300D-2 | -- | HPT300 | B1200 ×6.3m | 4.5 | 180 | 14850×2800×4000 |

K6H300V-2 | -- | HPT300 | B1200 ×6.3m | 4.5 | 180 | 14850×2800×4000 |

K6S1860-1 | S5X1860-3 | -- | 31000×10m | -- | 200 | 15200×3000x4200 |

K652160-1 | S5X2160-3 | -- | B1000×10m | -- | 200 | 15200×3000×4200 |

K652460-1 | 55X2460-3 | -- | B1000×10m | -- | 200 | 15200×3000×4200 |

K6H300S-2 | 3Y2S2160 | HPT300 | B1000 ×8.5m | -- | 180 | 15500×2700×4480 |

K6T160S-2 | 3YZ52160 | HST1605 | B1000×8,5m | -- | 250 | 15500×2700×4480 |

K6F12145-2 | 3YZ51860 | PFW1214Ⅲ | B1000 ×8.5m | -- | 250 | 15500×2700×4480 |

K6F1315S-2 | 3YZ52160 | PFW1315Ⅲ | B1000 ×8.5m | -- | 300 | 15500×3000×4480 |

K6V8522S-2 | 3YZS1860 | VSI5X8522 | B1000×8.5m | -- | 35 | 15500×2700×4480 |

K6V95325-2 | 3Y252160 | VSI5X9532 | B1000×8,5m | -- | 40 | 15500×2700x4480 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.