-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Stone Crushing Machine

Direct deal Quality Assurance Quick response Service worry free

Production capacity:50-1200t/h

Feed particle size:10-350mm

Applicable materials:River pebble, limestone, dolomite, granite, rhyolite, diabase, basalt, ferrous metal ore, etc

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

HPT multi-cylinder cone crusher is a typical crushing equipment for medium and fine crushing of hard materials. It is developed on the basis of spring cone crusher, and its basic structure is similar to spring cone crusher. It is used in mining, metallurgy, construction, chemical industry, electric power, transportation and other industries.

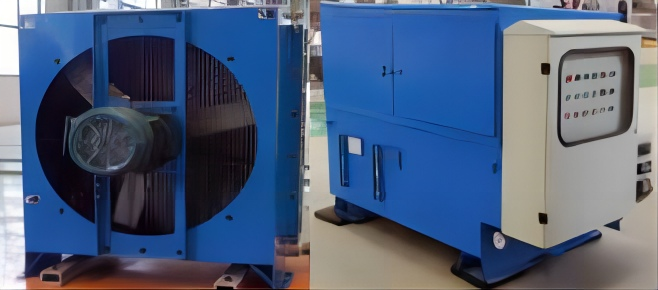

1.Integrated Hydraulic Lubrication System

HPT cone crushers are equipped with integrated hydraulic lubrication system and centralized automatic control system, decreasing the input cost of hydraulic lubrication. And the two systems can monitor the operating state in real time, ensuring that the equipment can run safely and stably.

2.Closed Side Setting (CSS) Adjusted by Hydraulic Moto

The equipment can remotely, accurately and continuously adjust the closed side setting through the forward and reverse rotation of hydraulic motor. Moreover, equipment’s downtime can be greatly shortened and disassembling and assembling can be quickly completed through hydraulic motor’s continu- ous rotation .

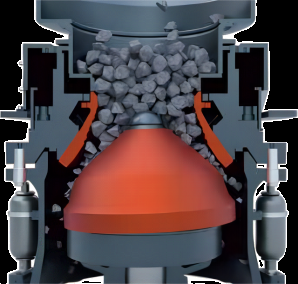

3.Inter-particle Crushing for Better Product Quality

The optimized structure and cavity, adapting interparticle crushing principle, ensure high performance of the crush- ers . It improves the interparticle crushing efficiency and decreases the wear of wear-resistant parts. And the quality of final products is highly improved as the product shape is cube sized and the content of fine product is high. The unique design lowers the operation cost of the equipment and the whole operation system.

4.Hydraulic Safety and Clearing

The safety system is made up by several large hydraulic protective cylinders and accumulators. Hydraulic protective cylinders not only provide the crushing force, overload protection and iron release when it is strained, but also clear the cavity when it is released which shortens the downtime greatly.

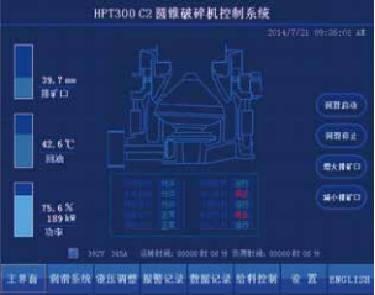

5.Automatic and Intelligent Control System

Centralized automatic control of hydraulic lubrication and electric provides several functions such as pressure mainte- nance, multi-mode operation, breakdown protection, alarm and parameter monitoring. More compact structure, safer operation and more convenient manipulation are achieved at the same time.

The working principle of the HPT multi-cylinder cone crusher is to drive the pulley and transmission part through the motor, the small bevel gear at the end of the transmission part meshes with the large bevel gear at the bottom of the eccentric sleeve, and the outer circle of the eccentric sleeve matches the inner hole of the body. When the multi-cylinder cone crusher is working, the eccentric sleeve pushes the body to do a rotary swing motion, thereby achieving material crushing .

The structure of the HPT multi-cylinder cone crusher includes components such as a motor, a pulley, a transmission part, a small bevel gear, an eccentric sleeve and a large bevel gear. The motor is connected to the transmission part through the pulley, the small bevel gear at the end of the transmission part meshes with the large bevel gear at the bottom of the eccentric sleeve, and the outer circle of the eccentric sleeve matches the inner hole of the body. During the crushing process, the moving cone generates an eccentric distance under the action of the eccentric sleeve to do a rotary swing motion, so that the crushing wall surface is sometimes close to the fixed cone surface and sometimes away from the fixed cone surface, so that the stone is continuously squeezed and impacted in the crushing chamber and crushed.

HPT multi-cylinder cone crusher is used for medium and fine crushing of hard materials, such as granite, river pebbles, quartz, iron ore, etc. It has good fine crushing and layered crushing effects and is suitable for processing medium and high hardness ores.

Model | Cavity | Feeding opening | Minimum discharge opening | Capacity | Nominal installed power | Max. installed power | Overall dimension |

HPT100 | (/) | (mm) | (mm) | (t/h) | (kw) | (kw) | (mm) |

C1 Extra Coarse | 140 | 19 | 75-140 | 90 | 90 | 1705×1510×1583 | |

C2 Coarse | 100 | 13 | 60-110 | ||||

M Medium | 70 | 9 | 50-100 | ||||

F1 Fine | 50 | 9 | 50-95 | ||||

F2 Extra Fine | 20 | 9 | 45-90 | ||||

HPT200 | (/) | (mm) | (mm) | (t/h) | (kw) | (kw) | (mm) |

C2 Coarse | 185 | 19 | 145-250 | 160 | 160 | 2135×1750×1927 | |

M Medium | 125 | 16 | 135-235 | ||||

F1 Fine | 95 | 13 | 115-220 | ||||

F2 Extra Fine | 75 | 10 | 90-190 | ||||

HPT300 | (/) | (mm) | (mm) | (t/h) | (kw) | (kw) | (mm) |

C1 Extra Coarse | 230 | 25 | 220-440 | 220 | 250 | 2725×2110×2871 | |

C2 Coarse | 210 | 19 | 190-380 | ||||

M Medium | 150 | 16 | 175-320 | ||||

F1 Fine | 105 | 13 | 145-280 | ||||

F2 Extra Fine | 80 | 10 | 110-240 | ||||

HPT400 | (/) | (mm) | (mm) | (t/h) | (kw) | (kw) | (mm) |

C1 Extra Coarse | 295 | 30 | 300-630 | 315 | 315 | 2775×2370×2295 | |

C2 Coarse | 251 | 25 | 285-560 | ||||

M Medium | 196 | 20 | 250-490 | ||||

F1 Fine | 110 | 13 | 180-345 | ||||

F2 Extra Fine | 90 | 10 | 135-320 | ||||

HPT500 | (/) | (mm) | (mm) | (t/h) | (kw) | (kw) | (mm) |

C1 Extra Coarse | 330 | 38 | 425-790 | 400 | 400 | 2800×3480×4050 | |

C2 Coarse | 290 | 30 | 370-700 | ||||

M Medium | 210 | 22 | 330-605 | ||||

F1 Fine | 135 | 16 | 270-535 | ||||

F2 Extra Fine | 95 | 13 | 220-430 | ||||

HPT800 | (/) | (mm) | (mm) | (t/h) | (kw) | (kw) | (mm) |

C1Extra Coarse | 350 | 38 | 570-1200 | 630 | 630 | 3970×3345×4235 | |

C2 Coarse | 299 | 32 | 520-1050 | ||||

M Medium | 265 | 25 | 475-950 | ||||

F1 Fine | 220 | 16 | 370-800 | ||||

F2 Extra Fine | 150 | 13 | 310-600 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.