-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Sand Washing Screening

Direct deal Quality Assurance Quick response Service worry free

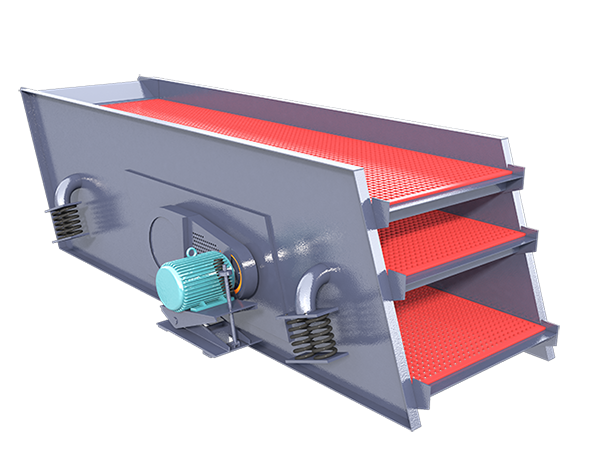

Production capacity:30-810t/h

Feed particle size:3-150mm

Applicable materials:Quartz, dolomite, dolomite, dolomite, quartz, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite, dolomite

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

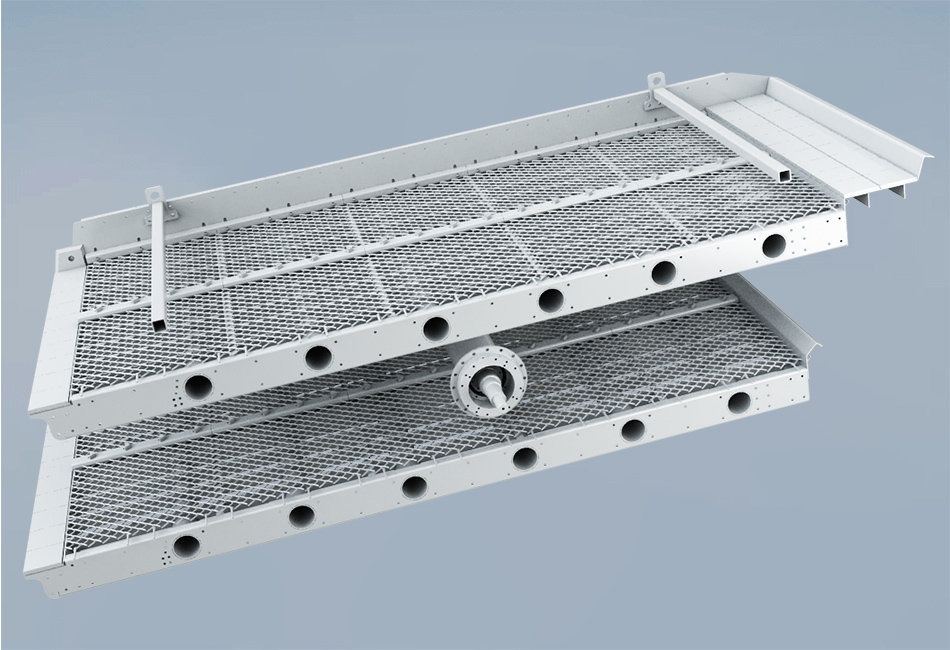

The motion of the vibrating screen is driven by the motor through the triangular belt with eccentric mass exciter, so that the sieve bed do periodic asymmetrical reciprocating mechanical vibration, so that the material layer on the screen surface is loose and left the screen surface is thrown up, so that the fine material can fall through the material layer, separated through the screen hole, and the material stuck in the screen hole is vibrated out, the fine material moves to the lower part, and is excluded through the screen.

1, YZS series - vibrating screen all connections are made of steel structure high-strength bolt connection to avoid welding stress, unique manganese steel sieve tensioning installation design, the replacement of thescreen is simple and convenient and the screen life is long.

2, YZS series - vibrating screen excisher adopts cylindrical or seat block eccentric structure, small screen adopts cylindrical lubricating oilself-lubrication, large screen adopts seat type circulating thin oil lubrication, and bearings adopt SKF, FAG, NSK and other imported brandsvibrating screen special bearings, the use of stable life is longer.

3, the unique eccentric pulley design effectively prevents the V-belt from beating with the sieve bed when it is running, and the spring is made of all-rubber, which effectively reduces the noise generated during the operation

of the sieve bed, and makes the sieve bed quickly cross the resonance zone, extending its overall life.

4, the frame adopts full assembly structure, convenient transportation and installation (the frame can be customized according to requirements).

The motor makes the eccentric block of the vibration exciter rotate at high speed through the triangle belt, which excites the screen box to produce a certain amplitude circular motion. The materials on the screen are continuously thrown by the impulse from the screen box on the inclined screen surface. When the materials meet the screen surface, the particles smaller than the screen hole are penetrated through the screen, so as to realize the classification.

Model | Sieve specification (mm) | layer | Mesh size (mm) | Max feeding size (mm) | Processing capacity (t/h) | Moto power (kw) | Vibrating Frequency (r/min) | Double amplitude (mm) |

2YK1237 | 1200X3700 | 2 | 3-50 | 200 | 30-100 | 5.5 | 970 | 5-9 |

3YK1237 | 1200X3700 | 3 | 3-50 | 200 | 30-100 | 7.5 | ||

2YK1548 | 4800X1500 | 2 | 3-100 | 400 | 30-275 | 15 | ||

3YK1548 | 4800X1500 | 3 | 3-100 | 30-275 | 15 | |||

2YK1848 | 4800X1800 | 2 | 3-100 | 56-330 | 18.5 | |||

3YK1848 | 4800X1800 | 3 | 3-100 | 56-330 | 18.5 | |||

4YK1848 | 4800X1800 | 4 | 3-80 | 56-330 | 22 | |||

2YK1860 | 6000X1800 | 2 | 3-100 | 65-586 | 18.5 | |||

3YK1860 | 6000X1800 | 3 | 3-100 | 65-586 | 22 | |||

4YK1860 | 6000X1800 | 4 | 3-100 | 65-586 | 30 | 980 | ||

2YK2160 | 6000X2100 | 2 | 3-100 | 81-720 | 22 | 980 | ||

3YK2160 | 6000X2100 | 3 | 3-100 | 81-720 | 30 | 970 | ||

4YK2160 | 6000X2100 | 4 | 3-100 | 81-720 | 37 | 980 | ||

2YK2460 | 6000X2400 | 2 | 3-150 | 100-810 | 22 | 970 | ||

3YK2460 | 6000X2400 | 3 | 3-150 | 100-810 | 30 | 980 | ||

4YK2460 | 6000X2400 | 4 | 3-150 | 150-850 | 37 | 980 | ||

2YK2470 | 7000X2400 | 2 | 3-100 | 180-900 | 30 | 980 | ||

3YK2470 | 7000X2400 | 3 | 3-100 | 180-900 | 37 | 980 | ||

4YK2470 | 7000X2400 | 4 | 3-100 | 180-900 | 45 | 980 | ||

2YK2480 | 8000X2400 | 2 | 3-150 | 190-940 | 30 | 980 | ||

3YK2480 | 8000X2400 | 3 | 3-150 | 190-940 | 37 | 980 | ||

4YK2480 | 8000X2400 | 4 | 3-150 | 190-940 | 45 | 980 | ||

2YK3070 | 7000X2400 | 2 | 3-100 | 220-1000 | 37 | 980 | ||

3YK3070 | 7000X2400 | 3 | 3-150 | 220-1000 | 45 | 980 | ||

4YK3070 | 7000X2400 | 4 | 3-150 | 220-1000 | 55 | 980 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.