-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Stone Crushing Machine

Direct deal Quality Assurance Quick response Service worry free

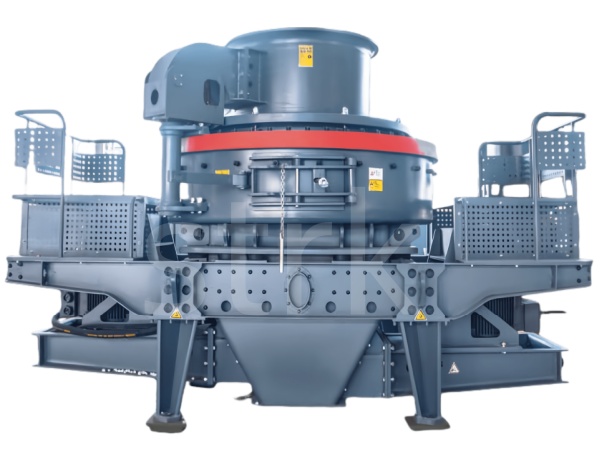

Production capacity:70-640t/h

Feed particle size:<60mm

Applicable materials:Pebbles, river pebbles, basalt, granite, quartzite, diabase, cement clinker and other hard and brittle materials.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

VSI vertical shaft impact crusher is the latest technology introduced from Germany by our company. It integrates high stability and high efficiency, and has three functions of crushing, sand making and shaping. The finished sand has full grain shape, reasonable gradation and stable output basis. It is recognized and recommended as a high-efficiency crusher for engineering construction worldwide. It is widely used in standard machine-made sand and stone shaping such as limestone, river pebbles, granite, mine tailings, stone chips, etc.; machine-made sand production and stone shaping in the engineering field of water conservancy and hydropower, high-grade highways, expressways, high-speed railways, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise buildings; fine crushing process before grinding in the mining field; material crushing in the building materials, metallurgy, chemical industry, mining, refractory materials, cement, abrasive and other industries.

1. The deep cavity rotor of VSI impact crusher has been perfectly designed, and the output has increased by 30%.

2. The direction of the side plate of VSI impact crusher can be changed, which improves the material utilization rate and the operation rate by 48%.

3. The combined wear hammer of VSI impact crusher only needs to be replaced, and the operating cost is reduced by 30%. Add a pair of auxiliary hammers to prevent damage to the main hammer and side plate.

4. The most critical wear-resistant material of VSI impact crusher adopts wear-resistant and high-temperature resistant materials from key areas of the United States.

5. The impact plate of VSI impact crusher adopts diamond shape to prevent damage to the side plate.

6. The bearings of VSI impact crusher adopt internationally renowned brands such as Japan, Sweden and the United States.

7. The perfect discharge port and smooth curve of VSI impact crusher reduce the resistance of material flow and greatly increase the output.

8. The dual-use bulk material plate of VSI impact crusher can easily switch between two feeding methods.

9. The VSI impact crusher uses a special sealing structure under the main shaft, which does not leak oil without sealing.

10. The VSI impact crusher is equipped with an original Japanese hydraulic cover opening device. The cover is easy to disassemble and install, and the internal inspection is convenient.

11. The VSI impact crusher uses a high-protection-level motor with high efficiency and low noise. The motor complies with IEC standards, with an insulation level of F and a protection level of IP54/55.

The working principle of the vertical shaft impact crusher is: after the raw material enters the impeller, it is accelerated and thrown out and directly hits the impact plate to be crushed. It can also be divided into two parts by the dividing plate, one part falls from all sides, and the other part enters the impeller and is accelerated and thrown out and collides, hits, and rebounds to the impact plate, and the cycle of impact is repeated. During the crushing process, small particles of material gradually form a material bed around the impact plate, which not only improves the crushing effect, but also protects the machine. The final artificial sand required is discharged downward from the discharge port.

Central feed handling capacity | General crushing (mm) | 454-486 | 344-368 | 264-283 | 167-179 | 109-117 |

Shaping (mm) | 454-583 | 413-442 | 317-342 | 200-215 | 131-140 | |

Maximum feed size | General crushing (mm) | ≤50 | ≤45 | ≤40 | ≤35 | ≤30 |

Shaping (mm) | ≤60 | ≤55 | ≤50 | ≤45 | ≤40 | |

Spindle speed | 900-1200 | 1000-1300 | 1100-1400 | 1200-1500 | 1300-1700 | |

Power (kw) | 2x315(400) | 2x250(350) | 400 | 264 | 150 | |

Overall dimensions (L X W X H mm) | 5700x2980 X4190 | 5500x2750 *3950 | 4880x2560 x3725 | 4640x2380 x3500 | 4100x2250 x3300 | |

Hydraulic lubrication station | Power (kw) | 0.75 | ||||

Security protection | Automatic shutdown without oil flow; Air cooling; Self-starting heating in winter | |||||

Flow rate | 4-16L | |||||

Mailbox heater power | 4KW | |||||

Technical data is subject to change without prior notice | ||||||

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.