-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Sand Washing Screening

Direct deal Quality Assurance Quick response Service worry free

Production capacity:

Feed particle size:

Applicable materials:

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

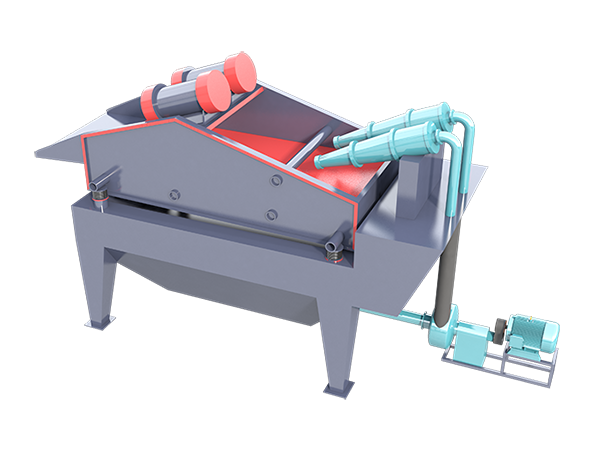

At present, most of the existing artificial sand production lines use the wet production process. No matter what form of sand washing machine is used, the disadvantage is that the loss of fine sand (particles below 0.2mm) is serious, and some even lose more than 20%. This not only loses the production, but also seriously affects the gradation of sand, resulting in unreasonable gradation, the increase of fineness modulus, and greatly reduces the product quality of machine-made sand. In the concrete mixing not only increases the amount of cement, improve the cost of business, and too much fine sand emissions, but also cause waste of land resources and environmental pollution. In response to the above problems, our company has successfully developed the LJ series of fine sand recovery equipment, which is a high-tech environmental protection equipment specially designed by our company to absorb foreign technology and combine the serious loss of fine sand in the actual production of customers.

1, the whole machine processing sludge capacity, purification and recovery efficiency is high, can effectively recover more than 0.2mm sand.

2, easy operation, easy installation, use and maintenance, low failure rate.

3, linear vibration dewatering sieve sieve out of the ballast has a good dewatering effect.

4. The screen body adopts buffer device, which can effectively reduce the working noise.

5. The abrasive resistant centrifugal slurry pump has the characteristics of simple structure, high universality, convenient operation, installation and maintenance;

6, thicker wear bearing parts and heavy brackets make it suitable for long-term transport of strong abrasive, high concentration slurry.

7. The hydraulic cyclone with structural parameters has mud and sand sorting indicators. The material is wear-resistant, corrosion-resistant, light weight, so it has the characteristics of easy operation and adjustment, economy and durability. Suitable for long-term maintenance-free use under harsh working conditions.

8, the unique recoil device can effectively prevent the slurry storage tank silt, so as to maintain the long-term normal operation of the equipment.

The special centrifugal slag pump will clean the sand and water mixture in the tank to the cyclone, the centrifugal classification of concentrated fine sand through the settling nozzle to the vibration dewatering screen, after

dehydration by the vibrating screen, the fine sand and water are effectively separated, a small amount of fine sand, mud, etc. through the return box and then back to the cleaning tank, mixed in the cyclone reflux mixed liquid, again

sent to the cyclone separation. When the liquid level of the cleaning tank is too high, it is discharged through the water outlet. The fineness modulus can be adjusted by changing the centrifugal pump speed, changing the slurry

concentration, adjusting the overflow water, and replacing the sand nozzle, so as to complete the three functions of cleaning, dehydration and classification.

Model | Pump motor Power (kw) | cyclone | Shaker Power (kw) | Flow capacity (m3/h) |

LJ300 | 15 | Single jet | 1.1x2 | 80-100 |

LJ350 | 18.5 | Single jet | 1.5x2 | 100-150 |

LJ500 | 18.5 | Double jet | 1.5x2 | 120-180 |

LJ700 | 18.5x2 | Double jet | 3.0x2 | 200-300 |

LJ900 | 18.5x2 | Three spray | 3.0x2 | 300-450 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.