-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Stone Crushing Machine

Direct deal Quality Assurance Quick response Service worry free

Production capacity:100-3200 t/h

Feed particle size:<1700 mm

Applicable materials:Bluestone, river pebble, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

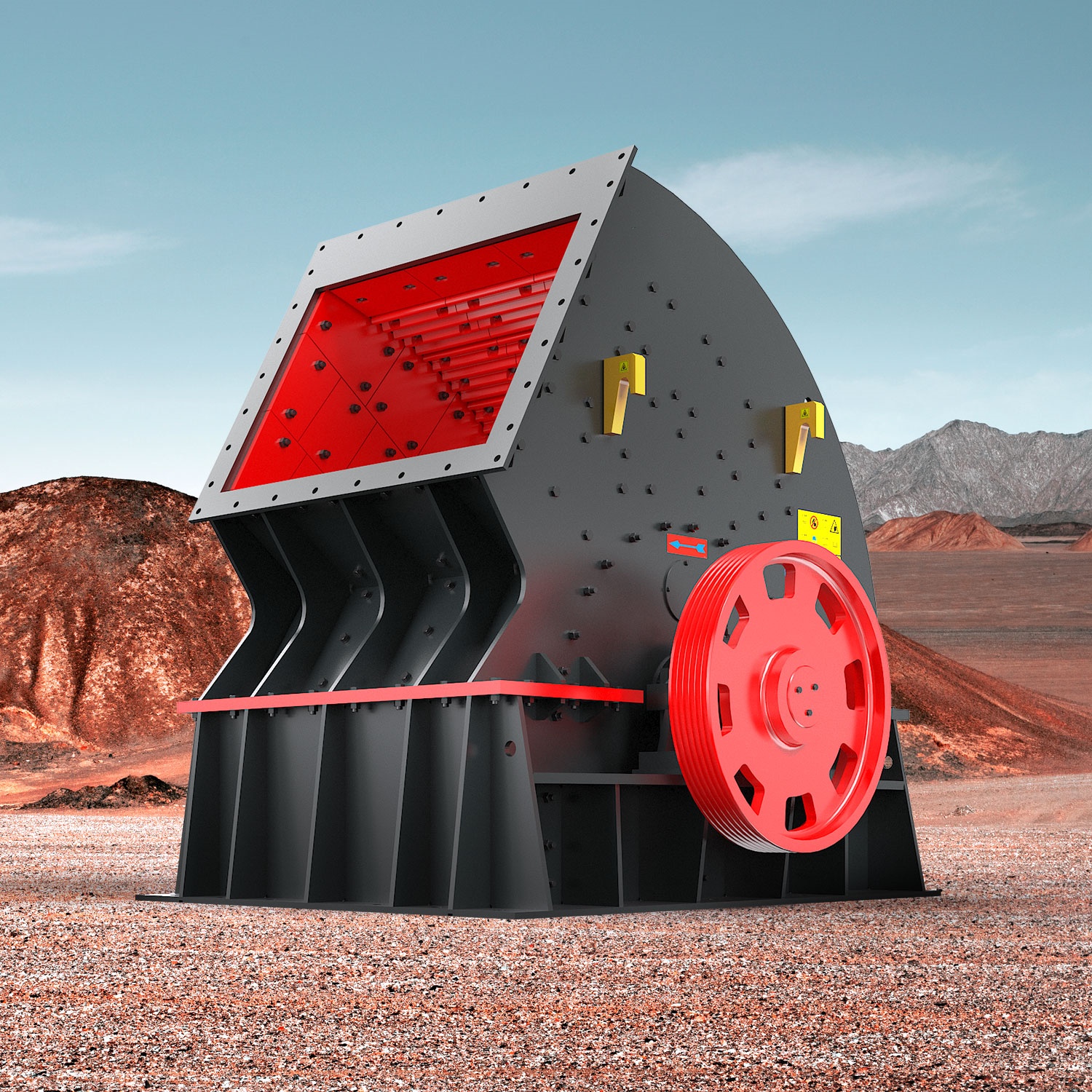

Hammer crusher relies on high-speed rotating hammer head to crush materials. It has the characteristics of simple structure, large crushing ratio, high production efficiency, etc. It can be used for dry and wet crushing. It is suitable for crushing medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highway, combustion and other departments. The equipment can adjust the wheel gap and change the discharge particle size according to user requirements to meet the different needs of different users.

Large crushing ratio :

Hammer crusher can effectively crush materials into smaller particles.

Wide range of applications :

Hammer crusher is suitable for cement, chemical, electric power, metallurgy and other industrial sectors, especially for crushing limestone, slag, coke, coal and other materials.

Low operating cost :

Hammer crusher system has small supporting power, low production cost, and is more energy-efficient than traditional three-stage crushing system.

Easy maintenance :

Hammer crusher has simple structure, easy maintenance and small wear.

Hammer crusher uses impact to crush materials. The main working part is the rotor with hammer head, which is composed of main shaft, disc, pin shaft and hammer head. The motor drives the rotor to rotate at high speed in the crushing chamber. The materials enter the machine from the upper feeding port and are crushed by the impact, impact and grinding of the high-speed hammer. The lower part of the rotor is provided with a sieve plate. The particle size smaller than the size of the sieve hole in the crushed material is discharged through the sieve plate, and the coarse particle size larger than the size of the sieve hole is blocked on the sieve plate, which continues to be hit and ground by the hammer, and is discharged through the sieve plate.

Model | Rotorspec | Feed opening(mm) | Feed particle size (mm) | Power(kw) | Capacity(t/h) | External dimensions(mm) |

PCZ1308 | 1310*790 | 800*850 | ≤500 | 132kw-4 | 100-160 | 2818*2100*2390 |

PCZ1512 | 1500*1160 | 1200*900 | ≤600 | (160kw-4)*2 | 250-400 | 3220*2520*2800 |

PCZ1615 | 1675*1510 | 1480*1200 | ≤650 | (220kw-4)*2 | 400-800 | 3665*2915*3440 |

PCZ1815 | 1776*1510 | 1480*1200 | ≤650 | (250kw-4)*2 | 400-900 | 3822*2912*3436 |

PCZ1820 | 1800*1964 | 2000*1200 | ≤800 | 800kw-6 | 800-1500 | 3474*3822*3520 |

PCZ2020 | 1920*2000 | 2010*1200 | ≤800 | 800kw-6 | 1200-1600 | 4160*3920*3520 |

PCZ2122 | 2130*2260 | 2240*1505 | ≤1000 | 1000kw-6 | 1800-2200 | 4990*4385*4360 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.