-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Sand Making Machine

Direct deal Quality Assurance Quick response Service worry free

Production capacity:60-520t/

Feed particle size:<60mm

Applicable materials:Pebbles, river pebbles, basalt, granite, quartzite, diabase, cement clinker and other hard and brittle materials.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

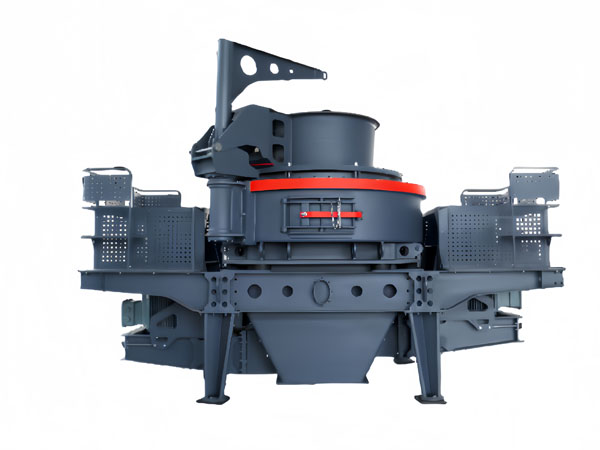

VSI6X vertical shaft impact sand making machine is the latest high-efficiency stone crushing and sand making equipment developed by our company. It has many national patent technologies. The machine integrates the company's many years of R&D experience and technical concepts, and adopts a newly designed four-open impeller structure and a special sealing structure to prevent oil leakage from the bearing cylinder.

1.VSI6X sand making machine :New design, efficient crushing;

2.VSI6X sand making machine:Technology upgrade, cost decreasing and benefit increasing;

3.VSI6X sand making machine:Unique design, quality assurance;

4.VSI6X sand making machine:Efficient working, easy maintenance;

VSI6X sand making machine:When entering into impeller, the raw material can be crushed directly by hitting impact plate after it is accelerated and threw out. The raw material can also be divided into two parts by material-dividing plate. One falls down from all around. The other enters into impeller and is accelerated, threw out and collides with the falling material and hit, rebound with impact plate. The circulation hits repeats. As the crushing is moving forward, small particle materials will gradually form a material bed around the impact plate which can improve the crushing effect and protect the machine. The desired artificial sand comes downwards though outlet finally.

Central feed handling capacity | General crushing (mm) | 454-486 | 344-368 | 264-283 | 167-179 | 109-117 |

Shaping (mm) | 454-583 | 413-442 | 317-342 | 200-215 | 131-140 | |

Maximum feed size | General crushing (mm) | ≤50 | ≤45 | ≤40 | ≤35 | ≤30 |

Shaping (mm) | ≤60 | ≤55 | ≤50 | ≤45 | ≤40 | |

Spindle speed | 900-1200 | 1000-1300 | 1100-1400 | 1200-1500 | 1300-1700 | |

Power (kw) | 2x315(400) | 2x250(350) | 400 | 264 | 150 | |

Overall dimensions (L X W X H mm) | 5700x2980 X4190 | 5500x2750 *3950 | 4880x2560 x3725 | 4640x2380 x3500 | 4100x2250 x3300 | |

Hydraulic lubrication station | Power (kw) | 0.75 | ||||

Security protection | Automatic shutdown without oil flow; Air cooling; Self-starting heating in winter | |||||

Flow rate | 4-16L | |||||

Mailbox heater power | 4KW | |||||

Technical data is subject to change without prior notice | ||||||

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.