-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Sand Washing Screening

Direct deal Quality Assurance Quick response Service worry free

Production capacity:80-800t/h

Feed particle size:≤100mm

Applicable materials:River pebble, granite, basalt, iron ore, limestone, quartzite, diabase, iron ore, gold ore, copper ore, etc

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

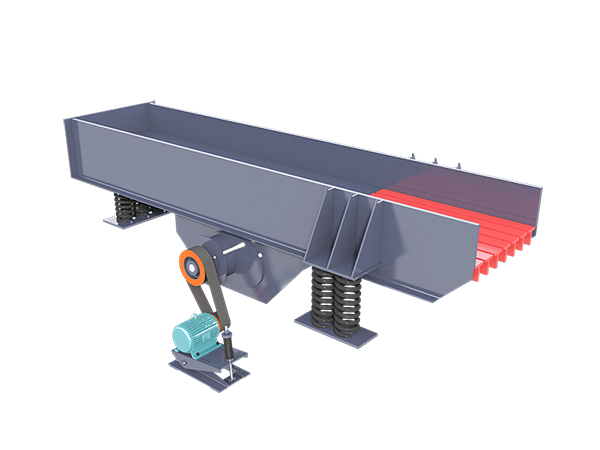

Vibrating feeder, also known as vibrating feeder, refers to a device that can evenly, regularly and continuously feed blocky and granular materials from the storage bin to the receiving device. In the sand and stone production line can be continuously and evenly fed for the crushing machinery, and the material is coarse screening, widely used in metallurgy, coal mine, mineral processing, building materials, chemical, abrasive and other industries crushing, screening combined equipment.

1. High efficiency and low operating costs

The double eccentric shaft is used as the excitation source, the amplitude is stable, the fluidity of the vibrated ore and rock material is guaranteed, and the blanking phenomenon is reduced, so the ore drawing capacity is large and the

efficiency is high. Simple structure, no rotating parts, less wearing parts, less vibration power consumption and significant energy saving.

2. High adaptability and low investment

Strong adaptability to all kinds of mineral and rock materials, especially viscous mineral and rock materials, and can work in dusty or water-containing environments; Small size, light weight, simple and compact, less investment,

cost-effective.

3. Stable performance and reliable work

Good machine continuity, adjustable exciting force; Electrical control with half wave rectifier, can stepless adjustment of the feed base, can be used in the automatic control of the production process, to achieve the automation of

the production process.

4. Low noise and no pollution

Machine working noise is low, can be used closed structure body to prevent dust pollution.

The vibrating feeder is composed of a feeding tank, a vibration exciter, a spring support, a transmission device, etc. The vibration source of the vibration feed of the channel body is the exciter, which is composed of two eccentric shafts (main and passive) and gear pairs. The motor drives the drive shaft through the triangle belt, and then rotates the passive shaft of the gear meshing on the drive shaft. The main and passive shafts rotate in reverse at the

same time, so that the channel body vibrates and the material flows continuously to achieve the purpose of conveying the material.

Model | Maximum feed size (mm) | Processing capacity (t/h) | Motor Model (mm) | Motor power (kw) | Feed tank (mm) |

GZD-300x85 | 450 | 55-80 | Y-160L-6 | 11 | 3000x850 |

GZD-380x96 | 500 | 90-150 | Y-160L-6 | 11 | 3800x960 |

GZD-420*110 | 600 | 120-320 | Y-180L-6 | 15 | 4200x1100 |

GZD-490*110 | 600 | 150-350 | Y-180L-6 | 15 | 4900x1100 |

GZD-490x130 | 750 | 250-450 | Y-200L-6 | 22 | 4900x1300 |

GZD -600*130 | 750 | 300-560 | Y-200L-6 | 22 | 6000x1300 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.