-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Grinding Mill

Direct deal Quality Assurance Quick response Service worry free

Production capacity:5-55t/h

Feed particle size:5-55t/h

Applicable materials:Mining, building materials, chemical, metallurgical, thermal power, coal and other industries.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

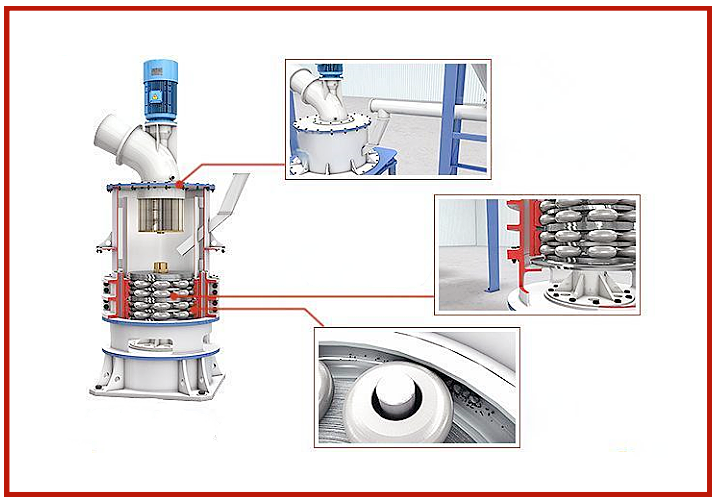

Ultrafine Grinding Mill is a new superfine powder (325-2500 mesh) production equipment developed through accumulating years of experience in grinding mill production, absorbing Swedish advanced machine manufacturing technology, and undergoing many years of tests and improvements. The SCM Ultrafine Grinding Mill is the result of combination of advanced Chinese and Swedish technologies. Meanwhile, it symbolizes the new development and new science in the grinding world.

Ultrafine Grinding Mill low investment cost

In the case of the same finenessit's less investment, less cost andshorter recycling cycle than jetmill .

Ultrafine Grinding Mill low wear parts loss

Ultrafine Grinding Mill safe and reliable operationin the grinding cavity

No rolling bearing and no screwsin the grinding cavity to avoid theproblem that the screws are easyto loose and damage themachine.

Ultrafine Grinding Mill more stable transmission

It adopts reducer transmissiondevice,which is more stable andmore efficient than traditional belttransmission .

Ultrafine Grinding Mill accurate particle size control

Using a new type of high-efficiencycage powder separator.frequenCycontrol,convenient particle sizead justment,accurate cutti ngparticle size,the fineness of thefinished product can reachD97≤5um.

Ultrafine Grinding Mill environmental protection

Using the high-effciency puse dustcollector, which has high dustcollection efficiency and no dust. Andit is also equipped with a silencer anda soundproof room,which greatlyreduces noise and meets the latestnational environmental protectionstandards.

...

Ultrafine Grinding Mill material is broken into less than 10mm by the jaw crusher, lifted to the storage hopper by the bucket elevator, and then quantitatively fed into the host cavity by the feeder for grinding. The grinding roll installed on the turntable rotates around the central axis and swings outwards horizontally under the action of centrifugal force, so that the grinding roll compacts the grinding ring and spins around the grinding roller pin at the same time. The grinding roller is divided into four layers (HCH780 is a three-layer arrangement), and the material is successively crushed by each layer of grinding roller and grinding ring. The ground powder does not fall on the chassis due to the action of gravity, and is blown to the classifier above the main engine for screening under the action of air flow of the blower. The dust collector is collected and discharged through the discharge valve, which is the finished product. The purified air flow flows into the blower through the upper residual air pipe. The air flow in the remaining pipes flows under negative pressure except for the positive pressure from blower to the grinding chamber.

Model | HGM880 | HGM980 | HGM1080 | HGM1280 | HGM1680 | |

Grinding roller and ring Number of tracks | Number of rolls (PCS) | 21 | 24-32 | 36 | 40-44 | 30-40 |

Number of loops (number) | 3 | 3-4 | 4 | 4 | 4 | |

Feed size (mm) | ≤20 | |||||

Finished product output (kg/h) | 500-5000 | 600-6500 | 1000-8500 | 1500-12000 | 5000-2500 | |

Fineness of finish | Micron | Mar-45 | ||||

MM | 3250-325 | |||||

Motor power (KW) | Host machine | 55 | 2×45 | 110 | 160 | 315 |

Powder separator | 18.5 | 22 | 37 | 45 | 185×5 | |

Air blower | 45 | 55 | 75 | 2×55 | 90×2 | |

Screw conveyor | 3 | 3 | 3 | 2-4 | 2 | |

Unloader | 2×0.75 | 2×0.75 | 2×0.75×1.1 | 4×1.1 | 1.5×2.075×2 | |

Air compressor | 7.5 | 15 | 15 | 2×15 | 55 | |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.