-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Grinding Mill

Direct deal Quality Assurance Quick response Service worry free

Production capacity:20-350t/h

Feed particle size:≤25

Applicable materials:MB rod mills are widely used in metal and non-metal mines, water conservancy, glass building materials, and artificial sand making industries that require uniform product particle size and less fine material.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

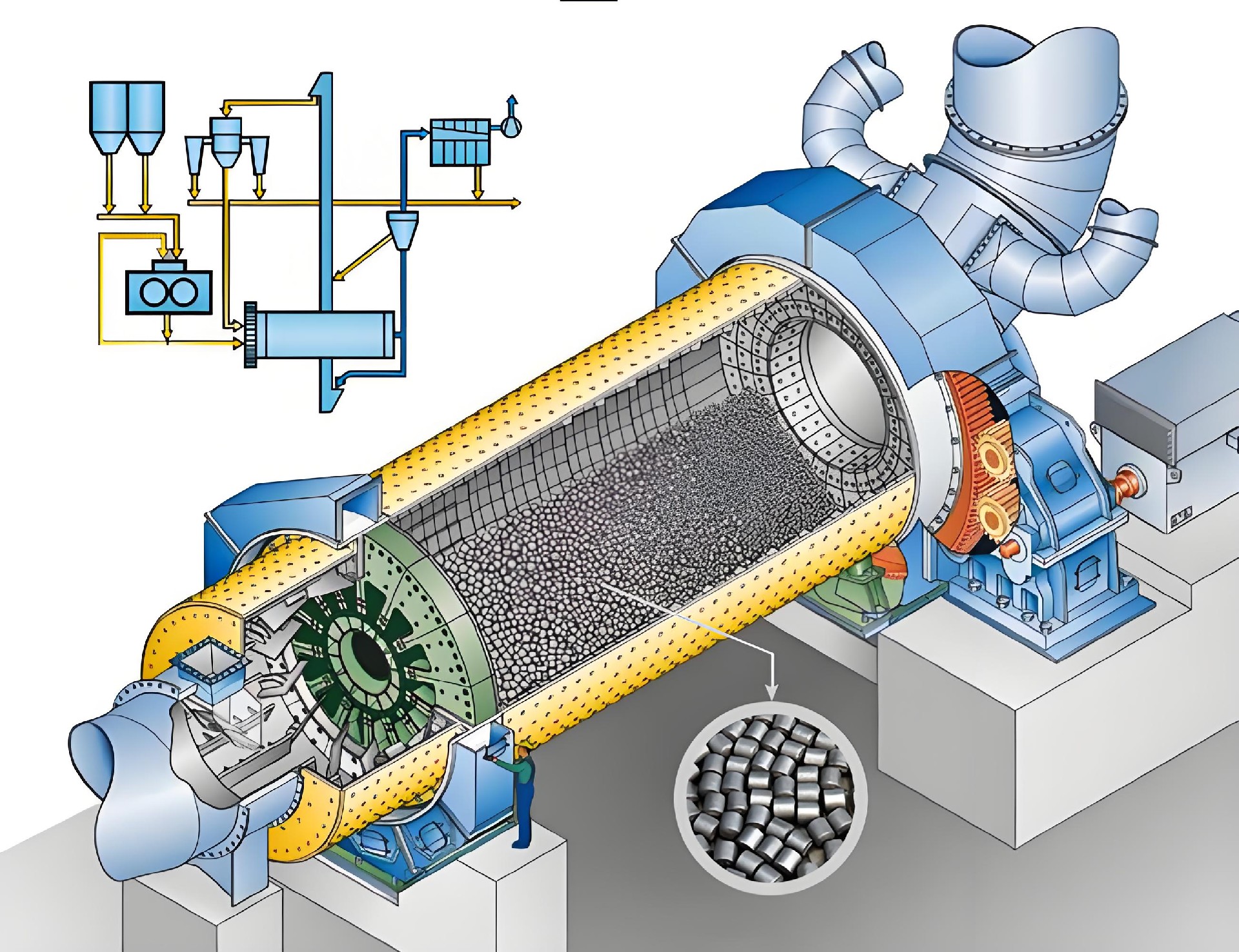

crusher@strkmac.com Hotline:+8613666220166

A rod mill is a type of mill in which the grinding material loaded inside the cylinder is a steel rod. The rod mill is generally a wet overflow type and can be used as a primary open circuit grinding machine. It is widely used in the primary grinding of artificial stone and sand, beneficiation plants, chemical plants, and power departments. The grinder is mainly composed of a motor, main reducer, transmission part, cylinder part, main bearing, slow transmission part, feed part, discharge part, annular seal, thin oil lubrication station, large and small gear spray lubrication, foundation part, etc. The main reducer has a parallel shaft and a hard tooth surface. A rod mill is an asynchronous motor connected to a small gear through a reducer, which directly drives the surrounding large gear to reduce speed and rotate, driving the rotation part to rotate. The cylinder is equipped with an appropriate grinding medium - steel rod. The grinding medium is continuously fed into the cylinder by the feeding part under the action of centrifugal force and friction force, and the material to be ground is crushed by the moving grinding medium. The product is discharged from the machine through overflow and continuous feeding force for the next processing step. It provides a detailed introduction to its working principle, structure, type, grinding medium, purpose, installation, and installation precautions.

1.Uniform discharge particle size and wide applicability

By using controllable feeding rod mill technology and combining with actual grinding materials, suitable grinding bodies are used. The grinding medium is in linear contact with the ore, making its discharge particle size more uniform and yield higher. It can be suitable for ores with different hardness.

2.The discharge particle size can be adjusted

Equipped with a built-in fineness control device, the particle size of the discharged material can be easily adjusted. A screening device can be added to the discharged material to ensure that it does not produce excessive grinding and does not mix unqualified products with the finished product.

3.Low power and large processing capacity

Compared to older equipment, it saves more than 40% of power and contains less coarse particles and slime. When used for rough grinding, the processing capacity of the rod mill is greater than that of the ball mill of the same specification.

4.Multiple models to choose from

There are two types of rod mills: dry and wet. Wet rod mills can be divided into three types according to the discharge method: overflow type rod mills, open type rod mills, and peripheral type rod mills. Users can choose according to their actual situation.

A rod mill is an asynchronous motor connected to a small gear through a reducer, which directly drives the surrounding large gear to reduce speed and rotate, driving the rotating part to rotate. The cylinder is equipped with an appropriate grinding medium - steel rod. The grinding medium is continuously fed into the cylinder by the feeding part under the action of centrifugal force and friction force, and is crushed by the moving grinding medium. The product is discharged from the machine through overflow and continuous feeding force for the next processing step.

型号 | 筒体尺寸 | 有效容积 | 装球量 | 筒体转速 | 功率 | 排矿粒度 | 生产能力 |

Model | Cylinder size(mm) | volume(m³) | Ball loading(t) | Rotary Speed (r/min) | Power(kw) | Output SizeCapacity(mm) | Capacity(t/h) |

WPZ2136 | φ2100×3600 | 11.0 | 16 | 21 | 210 | 0.2-3 | 100-130 |

WPZ2445 | φ2400×4000 | 18.4 | 27 | 19.4 | 355 | 0.8-5 | 200-250 |

WPZ2745 | φ2700×4500 | 23.4 | 35 | 18.3 | 250 | 0.8-5 | 280-320 |

WPZ3050 | φ3000×5000 | 31.9 | 46 | 17.3 | 355 | 0.8-5 | 300-370 |

WPZ3250 | φ3200×5000 | 35.7 | 52 | 16.37 | 355 | 0.8-5 | 400-500 |

WPZ3260 | φ3200×6000 | 43.1 | 62 | 16.37 | 400 | 0.8-5 | 470-540 |

WPZ3460 | φ3400×6000 | 49.2 | 72 | 15.53 | 500 | 0.8-5 | 580-720 |

WPZ3660 | φ3600×6000 | 55.1 | 80 | 14.98 | 800 | 0.8-5 | 700-800 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.