How does the stone crusher work in hydropower dam construction?

In the hydropower dam construction project, the stone crusher manufactured by Sandrek showed outstanding advantages and played a key role in the smooth progress of the entire project.

(The picture comes from the Internet)

1. Stone collection and primary crushing

Stone collection

First, it is necessary to mine the raw stones suitable for dam construction from the stone field. These raw stones are usually hard rocks such as granite and basalt. The mined raw stones vary in size, and some may be huge stones.

Primary crushing

The jaw crusher is used for primary crushing. The jaw crusher works by squeezing and crushing the stone. This is achieved by the regular movement of the movable jaw plate and the fixed jaw plate.

When the raw stone enters the crushing chamber of the jaw crusher, the motor rotates the eccentric shaft. This makes the movable jaw plate move back and forth towards the fixed jaw plate.

The raw stone is crushed by squeezing, splitting and bending between the two jaw plates. It crushes the boulder several meters wide into stones tens of centimeters long. This makes further crushing and processing easier.

The jaw crusher provided by Sandreck adopts a unique V-shaped cavity design, integrated motor installation, adjustable discharge port size, and high degree of automation.

2. Secondary crushing and shaping

After the initial crushing, a cone crusher or an impact crusher is used for secondary crushing.

The cone crusher mainly crushes stones by squeezing and grinding between the moving cone and the fixed cone.

When the stone enters the crushing chamber of the cone crusher, the moving cone swings. The eccentric sleeve drives this movement. As the cone moves, the stone is squeezed and ground between the moving cone and the fixed cone.

The cone crusher produced by Sandreck adopts a PLC control series, which can realize dynamic gap adjustment and has the characteristics of simple operation and convenient maintenance.

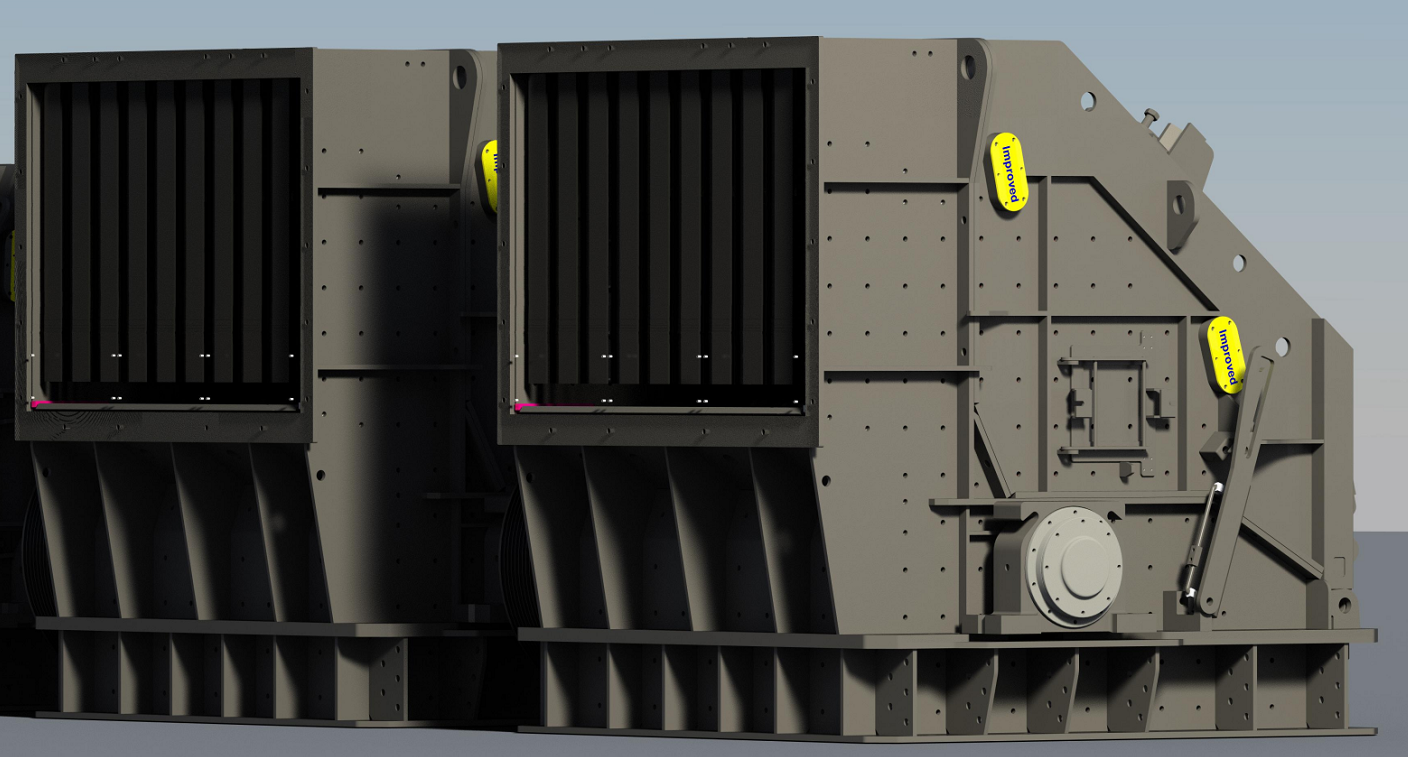

The impact crusher uses the plate hammer on the rapidly rotating rotor to crush the stone. The machine quickly ejects the stone onto the impact plate for further crushing. At this stage, the stone can be broken into smaller fragments. The size of these fragments ranges from a few centimeters to more than ten centimeters.

The impact crusher produced by Sandreck adopts a five-row heavy-duty rotor with a large moment of inertia and impact crushing particles. The hammer is made of highly wear-resistant materials to extend its service life.

3. Shaping treatment

In some cases, the stone will be used for specific purposes. This includes stones used for dam surfaces or concrete aggregates. In these cases, a shaping crusher is used.

The impact crusher accelerates the stone through a high-speed rotating impeller, causing the stone to collide with other objects (such as the impact liner, the stone itself), thereby crushing and shaping the stone, making the stone edge more rounded, improving its filling effect in the dam structure and the working performance of concrete.

The impact crusher produced by Sandreck has a number of patented technologies and has three major functions: crushing, sand making, and shaping. The finished sand particles are full, the grading is reasonable, and the output is stable. It is an efficient crusher recommended for factory construction.

4. Screening and grading

The crushed stone will be screened by a vibrating screen. A vibrating screen is a device that uses a vibrating motor to generate high-frequency vibrations.

Sanreck mining heavy-duty vibrating screen adopts unique cold riveting technology, modular SV super vibrator, large equipment conveying capacity, high screening efficiency and strong processing capacity.

Screening is carried out according to the size of the sieve hole. For example, a concrete dam can be screened using a multi-layer vibrating screen configured with aperture size.

5. Gradual storage and application

The screened stones will be transported to different storage areas according to their particle size.

For the main structure of the dam, workers use coarse stones as core support. Fine stones fill the gaps between coarse stones. This helps to increase the density of the dam.

For concrete dams, different types of aggregates are used to make concrete. This is based on design requirements. The right aggregate helps to ensure the strength and good performance of concrete. In this way, the concrete can effectively withstand the water pressure and weight of the dam.

The jaw crushers, cone crushers, impact crushers, vertical shaft sand making machines, etc. produced by Sandreck crusher manufacturers play an irreplaceable role in concrete.