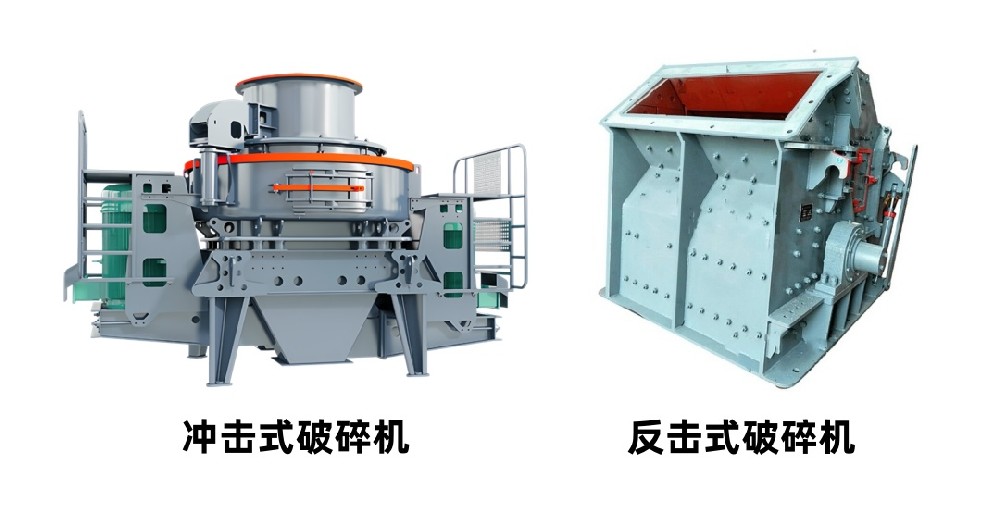

Difference between Impact Crusher and Counterattack Crusher:

Impact crusher and counterattack crusher are two kinds of crushing equipment commonly used in mines. The difference between the two is mainly reflected in the following aspects:

1. The working principle is different:

The impact breaking adopts the "stone beating stone" working mode, and the materials enter each crushing chamber through the feeder to grind and impact each other, the sand production efficiency is higher, and the finished sand grain type processed is better.

Counterattack breaking is also carried out by impact force, but different from impact breaking, the material is broken by interaction with the plate hammer after entering the crushing chamber driven by the rotor, and the finished sand produced is a cube, without tension and cracks.

2.Feed granularity is different:

The feed particle size of the impact break is mostly limited to about 50mm, and the discharge particle size is about 0~5mm. The impact break is a kind of fine crushing equipment, so if the size of the sand and stone materials is large, it is necessary to go through the jaw crusher or cone crusher after coarse crushing.

Counter energy crushing feed particle size does not exceed 500mm, compressive strength does not exceed 350MPa of various coarse, medium and fine materials, the discharge particle size can be adjusted according to the user's production needs, is a medium fine crushing equipment, the size of the sand material is not too limited.

3.The scope of application is different:

Impact crusher is suitable for the treatment of hardness, brittleness strong materials, such as limestone, coal and so on. Counterattack crusher is suitable for dealing with small hardness, strong plasticity, medium hardness and below the material, such as bluestone, limestone, etc., not suitable for crushing river pebbles, pebbles and other hardness, high strength materials.

4. Different wearing parts:

The impact breaking machine uses high quality materials, high sand production cost, very reliable and durable, and its wearing parts are mainly in the throwing head. At present, the new type of impact break adopts the combined design of wear-resistant blocks, so it does not need to be replaced frequently in daily operation, and only needs to replace the wear part when wear occurs, the maintenance cost is low, and the impact block shape is improved into a diamond shape to avoid damage to the vertical plate after material impact wear. The vulnerable parts that are broken are mainly in the hammer head, so the replacement of the hammer head is more frequent.