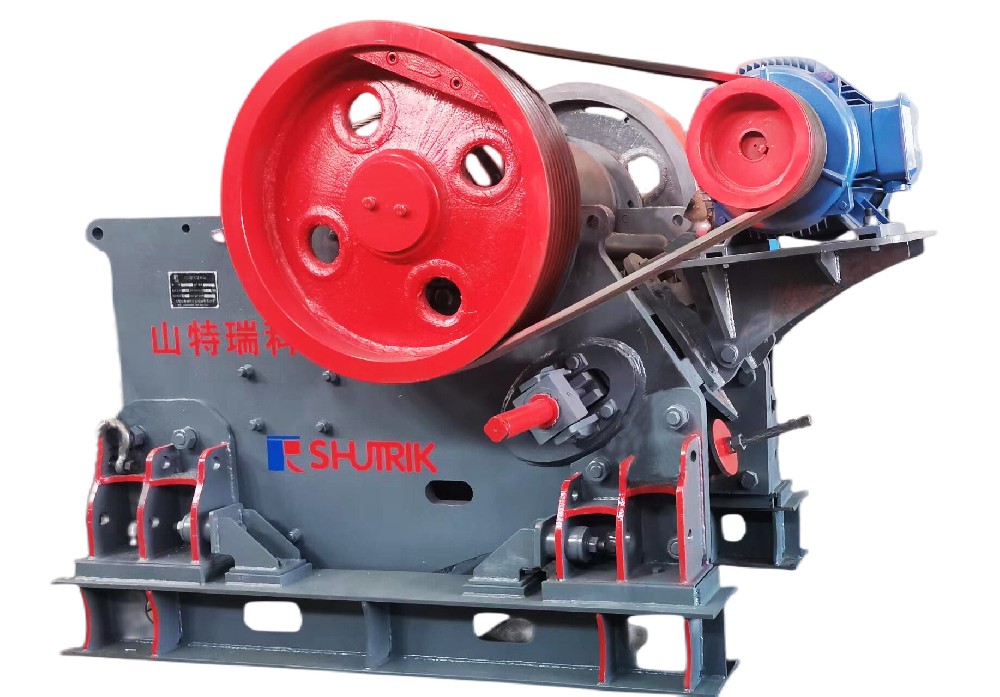

Possible failure of Jaw Crusher and elimination method

Jaw Crusher is one of the most commonly used equipment in the mining machinery industry, which is usually used for the rough breaking and medium crushing industry of materials. Today, we will tell you about various failures and their respective solutions due to improper operation or machine parts in the operation process.

1.The flywheel continues to run and the crushing work is suspended, the elbow plate falls off from the groove, the reason for this problem is that the spring or tie rod is broken and the tie rod nut is relaxed, the solution is to replace the spring and tie rod, and tighten the nut.

2. When the jaw plate fastener slack, there will be a mobile jaw plate jumping fault, then need to tighten the wedge nut to solve the fault.

3.Reasons for excessive temperature rise in the bearing seat or moving jaw of the rack may include bearing oil break or too much oil injection,oil hole blockage,flying-fluted wheel offset position, etc. solutions include timely and quantitative refueling,cleaning oil holes,adjusting the position of flying-fluted wheel counterweight, etc.

In addition, insufficient grease or grease pollution will also occur in the bearing temperature is too high, you need to add an appropriate amount of grease or replace the grease after cleaning the bearing, if the bearing is completely damaged, you need to replace the bearing.

4.Adjusting the equipment when the material loss port does not relax the spring will cause the spring to break, so in the adjustment of the material discharge port first to relax the spring, after adjusting properly tighten the tie rod nut.

5.When the equipment is running, the knocking sound generated at the back of the machine is because the tie rod is not tightened, resulting in the elbow impacting the jaw and adjusting the elbow pad in the seat slot, so the tie rod nut needs to be properly tightened.

These faults and their solutions cover most of the problems that the European jaw crusher may encounter in the process of use, through correct maintenance and timely fault treatment, can ensure the normal operation of the crusher and extend the service life.