-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Sand Making Machine

Direct deal Quality Assurance Quick response Service worry free

Production capacity:20-200T/H

Feed particle size:Widely used in hydropower, highways, construction waste treatment and artificial construction aggregate processing

Applicable materials:Granite, marble, basalt, limestone, quartz stone, river pebble, iron ore, copper ore, etc

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

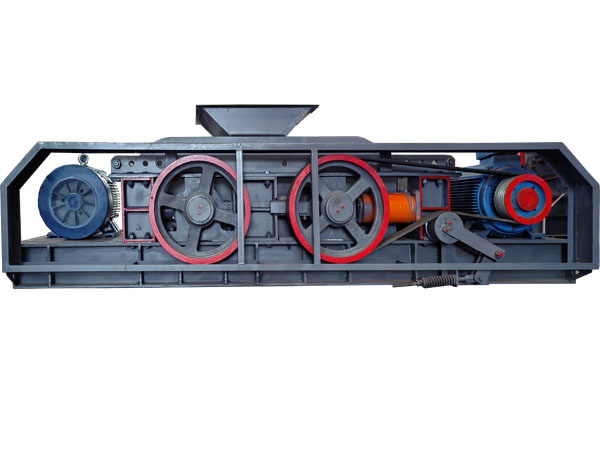

The roller crusher is configured with two crushing rollers, according to the granularity required by the user, the distance between the crushing rollers of the roller crusher can be adjusted to achieve the size of the discharge particles. The roller crusher is suitable for fine crushing operation with feed size less than 30mm and finished product size requirement ≥ 5mm.

1. Planetary gear reduction structure

Suitable for planetary secondary deceleration structure, so that theequipment is more durable, higher quality, stable and reliable.

2. Full hydraulic system

The hydraulic adjustment system is adopted, and the hydraulic cylinder hasthe automatic balancing function, so that the thrust of the two cylinders isbalanced, the parallel of the roller, and the width of the discharge port is

consistent; The operation is simple, just click to play - forward - back button,you can complete the adjustment of the size of the machine discharge, nitrogencylinder has a good protection equipment function, when the equipment in

operation encountered hard/metal materials can play a buffer role.

3. Thickened roll cover

The thickened roller cover makes the service life of the roller coverlonger, generally in 3 to 5 years

4. Thin oil automatic lubrication system

No need to refuel every day, automatic lubrication system, making theoperation more convenient.

5. Double motor power foot

Equipped with dual motor, judging, making the equipment more powerful andmore stable operation.

6. Small footprint

Compact structure, small footprint, flexible configuration, highreliability.

7. High output, low energy consumption

The output can be increased by 20%-30%, while the power consumption isreduced

The roller crusher is the use of two high-strength wear-resistant alloycrushing rollers, after the material enters the gap between the two rollers, theextrusion pressure and shear force of the relative rotation of the two crushingrollers, under the extrusion, shear and grinding, the material is broken intothe required particle size from the discharge port.

The two crushing rollers adopt the design mode of one fixed and onemovable. Under normal circumstances, the finished material at the discharge portis smaller than between the rolls. A small distance; When the hardness of the

debris is greater than the preset working pressure, the distance between the twocrushing rollers is adjusted by squeezing the spring, so as not to damage theequipment and extend the life of the crushing rollers;

Model | Feed size(mm) | Discharge size(mm) | Yield(th) | Motor power(kw) |

2PG-400×250 | ≤25 | 2-8 | 5-10 | 30×2 |

2PG-500×400 | ≤30 | 1-15 | 10-20 | 37×2 |

2PG-600×400 | ≤40 | 1-20 | 15-40 | 55×2 |

2PG-900×600 | ≤40 | 3-40 | 60-125 | 75×2 |

2PG-1200×1000 | ≤40 | 4-50 | 70-180 | 110×2 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.