A sand making machine is an equipment that converts various hard and brittle materials such as rocks, sand, and river pebbles into building sand with different particle sizes. The sand produced by this equipment has uniform particle size and high compressive strength, which is far more in line with building requirements than natural sand or sand produced by ordinary hammer sand hammers, and can significantly improve building quality. The sand making machine has the characteristics of reliable performance, reasonable design, convenient operation, and high work efficiency, and is widely used in construction, road, bridge and other engineering fields.

1. CNC sand making machine: It is a new type of sand making equipment developed by our company. The speed of the rotor is adjusted through a frequency conversion control device, combined with the gap adjustment between the hammer head and the crushing wall to control the adjustment of the discharge particle size and output. The discharge particle size can be controlled according to different customer needs, achieving one machine for fine sand, medium sand, and large sand, making it easy to adjust; The lubrication device is simple and convenient for oiling, with two oiling methods: manual and automatic, which can be freely switched to improve production efficiency; The crushing ratio is high, and materials around 100mm can directly enter the sand making machine for crushing, saving costs and low energy consumption.

2. Hammer type sand making machine: The electric motor drives the rotor to rotate at high speed in the crushing chamber, and the material is fed into the machine from the upper feeding port. It is crushed by the impact, shearing, and grinding effects of the high-speed running plate hammer. A sieve plate is installed at the lower part of the rotor, and particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate. It can be broken in both dry and wet forms, and the gap between the grate bars can be adjusted according to user needs to change the discharge particle size to meet the different needs of different users.

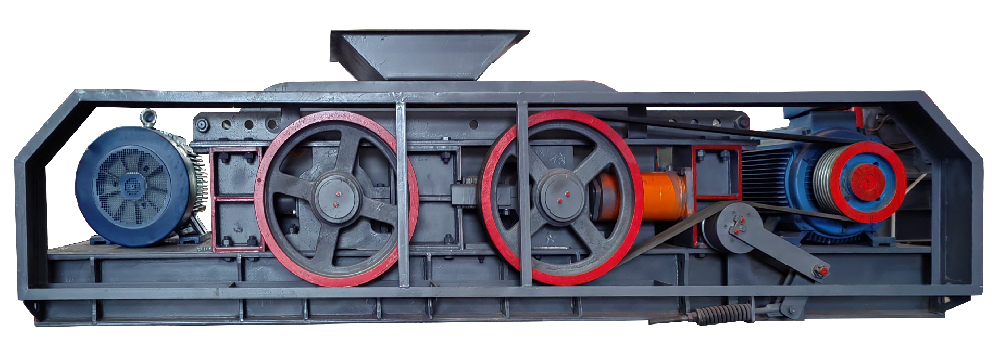

3. Roller sand making machine: suitable for medium and fine crushing operations of solid materials with a pressure resistance of less than 300Mpa and a moisture content of less than 35%. The roller sand making machine is equipped with two crushing rollers, and the discharge particle size is achieved by adjusting the distance between the crushing rollers of the roller sand making machine according to the user's particle size requirements.

4. TV95 sand making machine: After the material enters the sand making machine from the feeding hopper, it is divided into two parts by the material separation hanger. One part enters the high-speed rotating impeller chamber and is uniformly thrown into each flow channel of the impeller by the cloth cone in an umbrella shape. The speed increases instantly to 60-75 meters/second and is ejected from the flow channel mouth. A part of the material that falls from the upper material separation rack is impacted and crushed, while another part of the material is rebounded and obliquely impacted upwards to the top of the vortex chamber. A piece of material is subjected to two or more impacts, friction, and grinding crushing effects in the vortex chamber, and the crushed material is discharged from the lower discharge port.

- Prev: Model of Jaw Crusher

- Next: Roll Crusher