-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Grinding Mill

Direct deal Quality Assurance Quick response Service worry free

Production capacity:2-150(t/h)

Feed particle size:≤25

Applicable materials:It is widely used in ferrous and non-ferrous metal mines, non-metal mines, building materials, chemicals, electric power, coal, transportation, light industry and other industrial sectors .

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

It is widely used in ferrous and non-ferrous metal mines, non-metal mines, building materials, chemicals, electric power, coal, transportation, light industry and other industrial sectors . The high-efficiency and energy-saving ball mill produced by our company all adopt rolling bearing support instead of bearing sliding bearing support. Energy saving 10-20% .

1. Suitable for various materials, capable of continuous production, with large production capacity, and able to meet the needs of large-scale production.

2. The crushing ratio is large, reaching over 300, and it is easy to adjust the fineness of the product.

3. It can work moderately under various conditions, and can be produced by dry or wet methods. It can also combine dry grinding processes simultaneously.

4. The ball mill itself is reliable in operation and can operate continuously for a long time.

5. Double layered cylinder, special cooling loop, good cooling performance, fast discharge, simple maintenance and management.

6. There is a good sealing device to prevent dust from flying, which can reduce the specifications, investment, and power consumption of the electrostatic precipitator for treating waste gas.

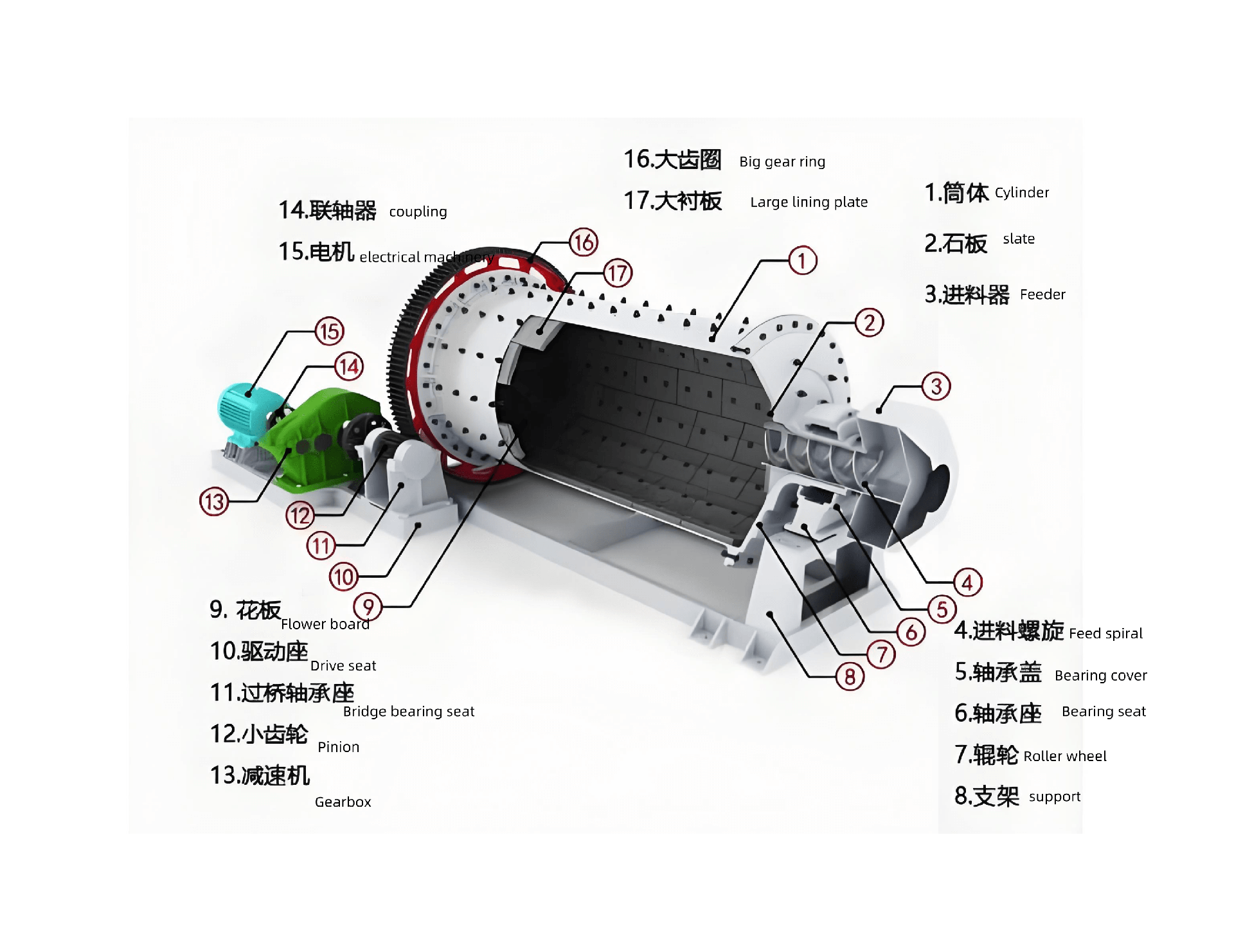

Energy saving ball mil is a commonly used crushing equipment, and its working principle is as follows:

1. Feeding: The material to be crushed is added to the grinding drum of the ball mill through the feeding device.

2. Grinding drum: The core component of a ball mill is the grinding drum, which contains a certain amount of grinding medium, usually steel balls. The material and steel ball rub, collide, and grind inside the grinding drum.

3. Motion mode: The grinding drum will rotate around its axis at a certain speed, and the steel ball will also move radially and angularly inside the grinding drum. This rotational and rolling motion allows the material to be thoroughly mixed and crushed in the grinding drum.

4. Crushing and crushing: When the grinding mill rotates, the grinding medium will crush the material and finely grind it. The material undergoes multiple collisions and grinding in the grinding drum, gradually reducing to the required particle size.

5. Discharge: The crushed material will be discharged from the grinding drum through the discharge device and collected into the corresponding aggregate device. In summary, the ball mill uses the grinding medium inside the grinding drum to crush and crush the material. Under the rotation of the grinding drum, the material continuously rubs and collides with the grinding medium, ultimately achieving the required particle size.

Model | RotarySpeed(r/min) | BallLoad(t) | Input Size(mm) | Output Size(mm) | Capacity(t/h) | Power(kW) | Weight(t) |

Φ900 × 1 800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

Φ900 × 3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Φ1200 × 2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

Φ1200 × 3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Φ1200 × 4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Φ1500 × 3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Φ1500 × 4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

Φ1500 × 5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Φ1830 × 3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4- 10 | 130 | 28 |

Φ1830 × 4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5- 12 | 155 | 32 |

Φ1830 × 6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5- 15 | 180 | 34 |

Φ1830 × 7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5- 17 | 210 | 36 |

Φ2100× 3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

Φ2100 × 4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

Φ2100 × 7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 |

Φ2200 × 4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

Φ2200 × 6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

Φ2200 × 7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

Φ2200 × 7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

Φ2400 × 4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.