-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Mobile Crushing Plant

Direct deal Quality Assurance Quick response Service worry free

Production capacity:120-640t/h

Feed particle size:≤50mm

Applicable materials:Most kinds of rocks, metallic ores, and other minerals, such as limestone, granite, marble, basalt, iron ore, copper ore, etc.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

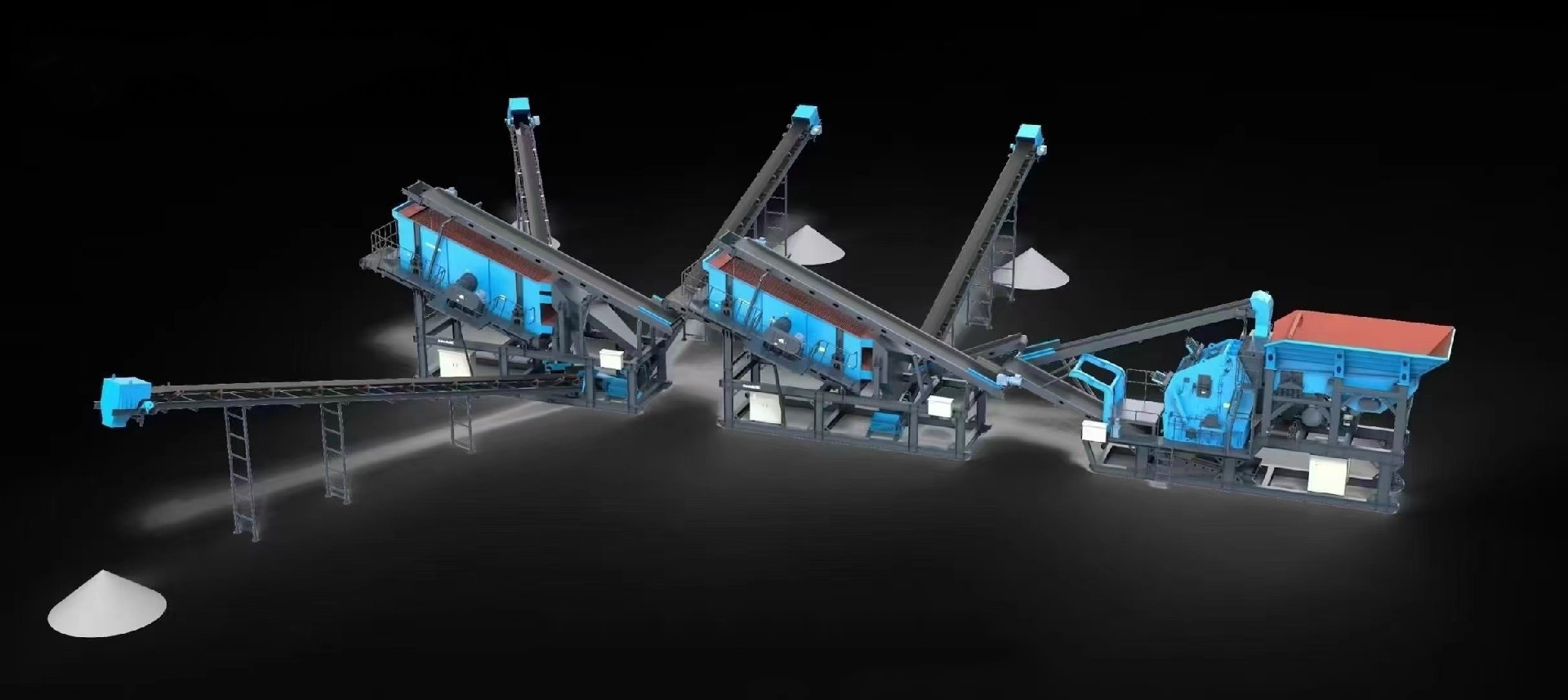

NK Portable Crushing Plant is a new type developed by the company. It is based on over ten years of experience in the crushing and screening industry along with the development of modern industrial technology. It can meet diverse customer needs, being of high quality, high capacity and high practicality. It mainly offers customers more comprehensive, systematic and flexible modular solutions.

1.Overall modular design

The Portable Crushing Plant is equipped with more than 30 models, with overall modular design and strong universal interchangeability. Various models can be assembled quickly, shortening the production cycle and meeting users' needs for fast delivery.

2.Simple body

NK Portable Crushing Plant adopts a simpler design concept, simplifies the overall structure of the equipment, and adopts a straight beam steel design for the frame, which increases the overall frame strength, and further improves the equipment reliability and production efficiency.

3.Integrated full vehicle system

NK portable mobile crushing plant are completely onboard, equipped with a hydraulic adjustment system. There is no need to disassemble parts during transportation, and it is easy to install on site. The belt conveyor is assembled on the vehicle, so there is no need for a crane or a belt conveyor on site. The whole vehicle equipment is flexible to install and move, and production and transfer can be quickly realized.

4. No basic installation required

In order to truly achieve the goal of eliminating the need for a concrete foundation, the NK portable mobile crushing plant is equipped with reasonable adjustable fixed outriggers while optimizing the stability of the entire vehicle. It can also be equipped with hydraulic outriggers. It only requires compacting the installation surface and fixing the outriggers to meet production needs, thus truly achieving installation without a foundation.

5.Integrated control system

NK mobile plant adopts a new vehicle-mounted integrated automatic control system, equipped with Siemens PLC centralized control, and set up a simple and clear touch screen design. It adopts "one-button start" and "one-button shutdown" to truly realize automated production. The equipment can start and stop as required according to the set sequence and time, maximizing the protection of the equipment and greatly reducing the failure rate of the equipment.

Extrusion crushing:

In a mobile jaw crusher, the moving jaw plate periodically moves closer to and away from the static jaw plate, squeezing the material in the crushing chamber. Under multiple forces such as squeezing, bending, and splitting, the material is crushed when the stress exceeds its strength limit.

Impact crushing:

A small mobile impact crusher uses a high-speed rotating rotor to drive a hammer or impact plate to impact the material at high speed. After the impact, the material has great kinetic energy and is crushed during the collision. It is suitable for materials with relatively low hardness and high brittleness.

Grinding crushing:

Some mobile crushers use two relatively rotating grinding parts (such as grinding discs or drums) for grinding, grinding the clamped material into fine particles under pressure and friction.

Mode | Feeding and screening equipmen | Crushing | Belt conveyor |

| Max.feed size | Transportation |

NK69J | GZD0936 | PE600×900 | B1000×9m | 6 | 500 | 13189×3852×4036 |

NK75J | GZD 0936 | PE750X1060 | B1000 ×9m | 6 | 630 | 13189×3852×4396 |

NK90J | GZD1142 | PE900X1200 | B1200 ×9m | 9 | 750 | 14488×5780×5200 |

NK100J | GZD0936 | C6X100 | B1000×9m | 6 | 630 | 13189×3852×4016 |

NK110J | GZD1142 | C6X110 | B1200 ×10m | 6 | 720 | 13638 ×4160×4930 |

NK1213CS | GZD1142、YZS1536 | CI5X1213 | B1000 ×8.4m | 6 | 550 | 16944×2324×5563 |

NK1315CS | GZD1345、YZS1845 | CI5X1315 | B1200×8.4m | 6 | 600 | 16944×2324×5563 |

NK160 HS | YZS1536 | HST160H | B1000 ×8.4m | 3 | 165 | 17914×3354×4700 |

NK300H | -- | HPT300 | B1000 ×8.4m | 3 | 180 | 15020×3290×4980 |

NK300 HS | YZ51536 | HPT300 | B1000 ×8.4m - | 3 | 180 | 17650×3420×4916 |

NK500 HS | YZS1845 | HPT500 | -- | 3 | 240 | 19890×3650×5603 |

NK1214 I5 | YZ51536 | PFW1214 III | B1000 ×8.4m | 3 | 250 | 17650×3420×4556 |

NK1315 I5 | YZ51536 | PFW1315 III | B1000 ×8.4m | 3 | 300 | 17650×3420×4800 |

NK1213 IS | YZS1536 | CI5X1213 | B1000 ×8.4m | 3 | 300 | 17650×3420×4556 |

NK9532V | -- | VSI5X9532 | B1000 ×8.4m | 3 | 40 | 15536×3350×4674 |

NK1145V | -- | VSI5X1145 | B1200 ×8.4m | 3 | 45 | 15536×3350×4970 |

NK1040V | -- | VSI6X1040 | B1200×8.4m | 3 | 45 | 15536×3350×4874 |

NK1505-3 | 3YZS1560 | -- | B1000×8m | -- | 250 | 14500×15440×6740 |

NK2005-2 | 2YZ51860 | -- | B1200×8m | -- | 300 | 14500×15440×6206 |

NK200S-3 | 3YZS1860 | -- | B1200 ×8m - | -- | 300 | 14500×15440×6740 |

NK300S-3 | 3YZS2160 | -- | B1200 ×8m | -- | 300 | 14500×16040×6740 |

NK4005-3 | 3YZ52460 | -- | B1400×8m | -- | 300 | 14500×16340×6740 |

NK160H-2M | 3SKX1560 | HST160H | B1200×8m | -- | 165 | 15562×3300×7114 |

NK300H-2M | 3SKX1860 | HPT300 | B1200×8m | -- | 180 | 15562×3500×7114 |

NK250H-2M | 3SKX2160 | HST250H | B1200×8m | -- | 185 | 16100×3800×7114 |

NK12141-2M | 3SKX1560 | PFW1214Ⅲ | B1000 ×8m | -- | 250 | 16605×3200×7100 |

NK12131-2M | 3SKX1860 | CI5X1213 | B1200×8m | -- | 300 | 16605×3500×7100 |

NK13151-2M | 3SKX2160 | C5X1315 | B1200×8m | -- | 300 | 16439×3800×7120 |

NK8522V-2M | 3SKX1860 | VSI5X8522 | B1200×8m | -- | 35 | 15680×3650×6565 |

NK9532V-2M | 3SKX2160 | VSI5X9532 | B1200 ×8m | -- | 40 | 16680×3950×6710 |

NK1040V-2M | 3SKX2160 | VS16X1040 | B1200×8m | -- | 45 | 16680×3950×711 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.