-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Sand Making Machine

Direct deal Quality Assurance Quick response Service worry free

Production capacity:2-150(t/h)

Feed particle size:≤25mm

Applicable materials:Coal, limestone, gypsum, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, etc.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

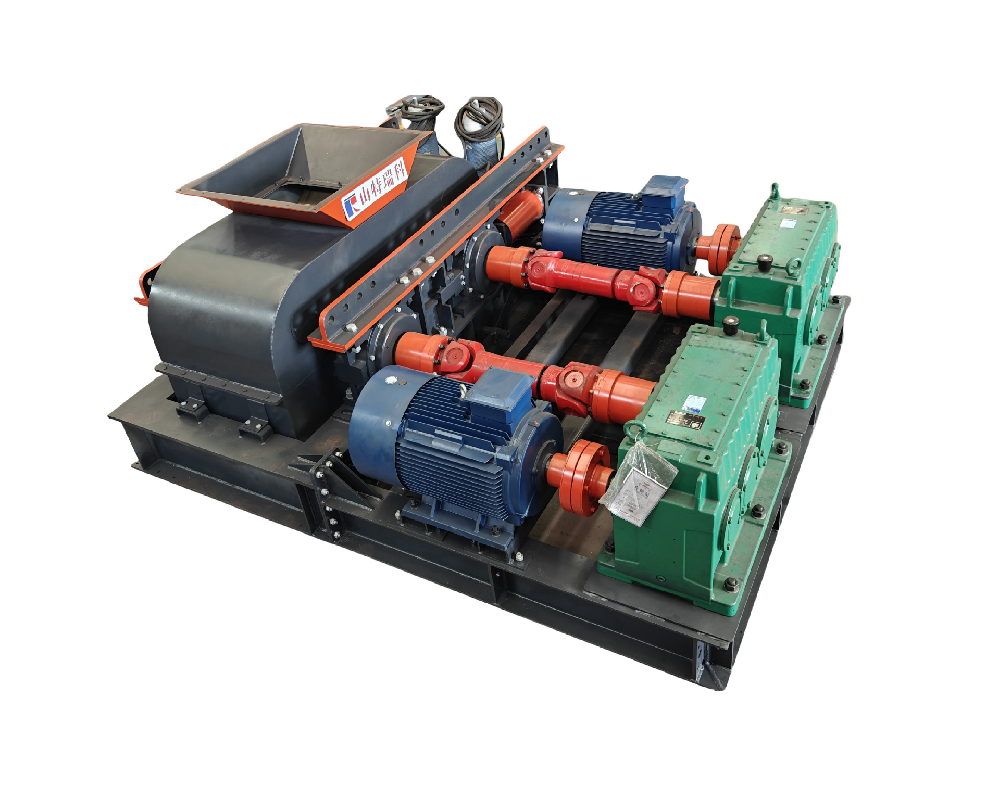

A double roll crusher, also known as a double roll sand making machine, is a core crushing equipment used for fine crushing and other high-precision crushing of materials. It mainly consists of crushing rollers, a frame, bearing housings, a transmission system, and a gap adjustment device.

Sandreck double roll crushers can produce cubic products with extremely low powder content and excellent particle shape. They effectively handle not only wet and sticky materials but also hard and highly abrasive materials.

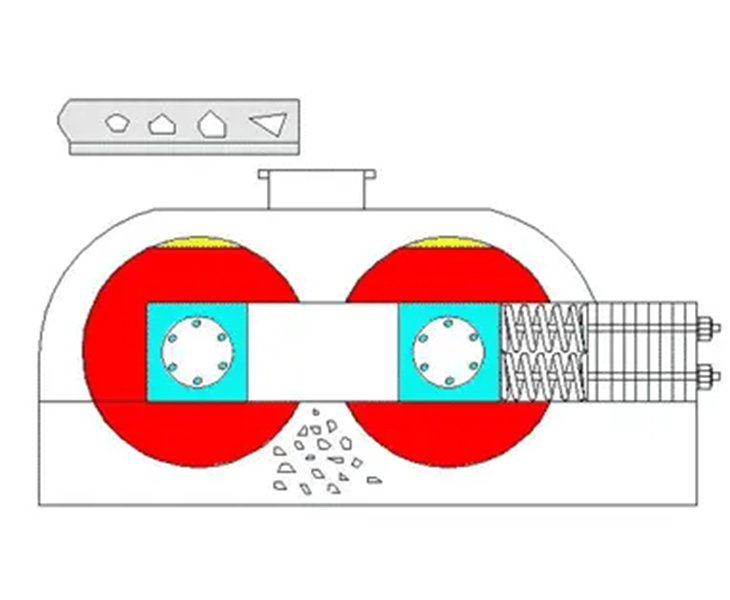

In addition, to adapt to different materials, the core roller skin of our double roll crusher can be customized to be smooth or toothed, thereby optimizing the crushing effect.

Sandreck's double roll crushers feature a compact and rigid structure, require little space, and are easily integrated into various crushing production lines.

Our double roll crushers have 80mm thick roll skins, typically lasting 3-5 years. The roll gap supports hydraulic stepless precise adjustment, eliminating the need for downtime and adapting to multiple particle size requirements.

Our double roll crushers incorporate overload protection and automatically avoid hard objects, reducing equipment failures and downtime.

Sandreck's double roll crushers feature a built-in thin oil lubrication system, eliminating the need for daily lubrication and simplifying operation.

Our direct-drive double roll crushers offer smooth operation, low noise, and energy savings, meeting green production standards.

The crushing process utilizes the extrusive force generated by two counter-rotating rollers to crush materials. The pressure between the two rollers is primarily controlled by a front spring or hydraulic pressure. The gap size directly controls the output particle size, achieving efficient crushing and producing products with regular particles and minimal fine powder.

Model | Feed size | Discharge size | Yield | Motor power (kw) |

2PG-400×250 | ≤25 | 2-8 | 5-10 | 30×2 |

2PG-500×400 | ≤30 | 1-15 | 10-20 | 37×2 |

2PG-600×400 | ≤40 | 1-20 | 15-40 | 55×2 |

2PG-900×600 | ≤40 | 3-40 | 60-125 | 75×2 |

2PG-1200×1000 | ≤40 | 4-50 | 70-180 | 110×2 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.