-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Grinding Mill

Direct deal Quality Assurance Quick response Service worry free

Production capacity:1-15T/h

Feed particle size:<60mm

Applicable materials:Calcite, chalk, calcium carbonate, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, palygorskite, rectorite, diatomite, barite

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

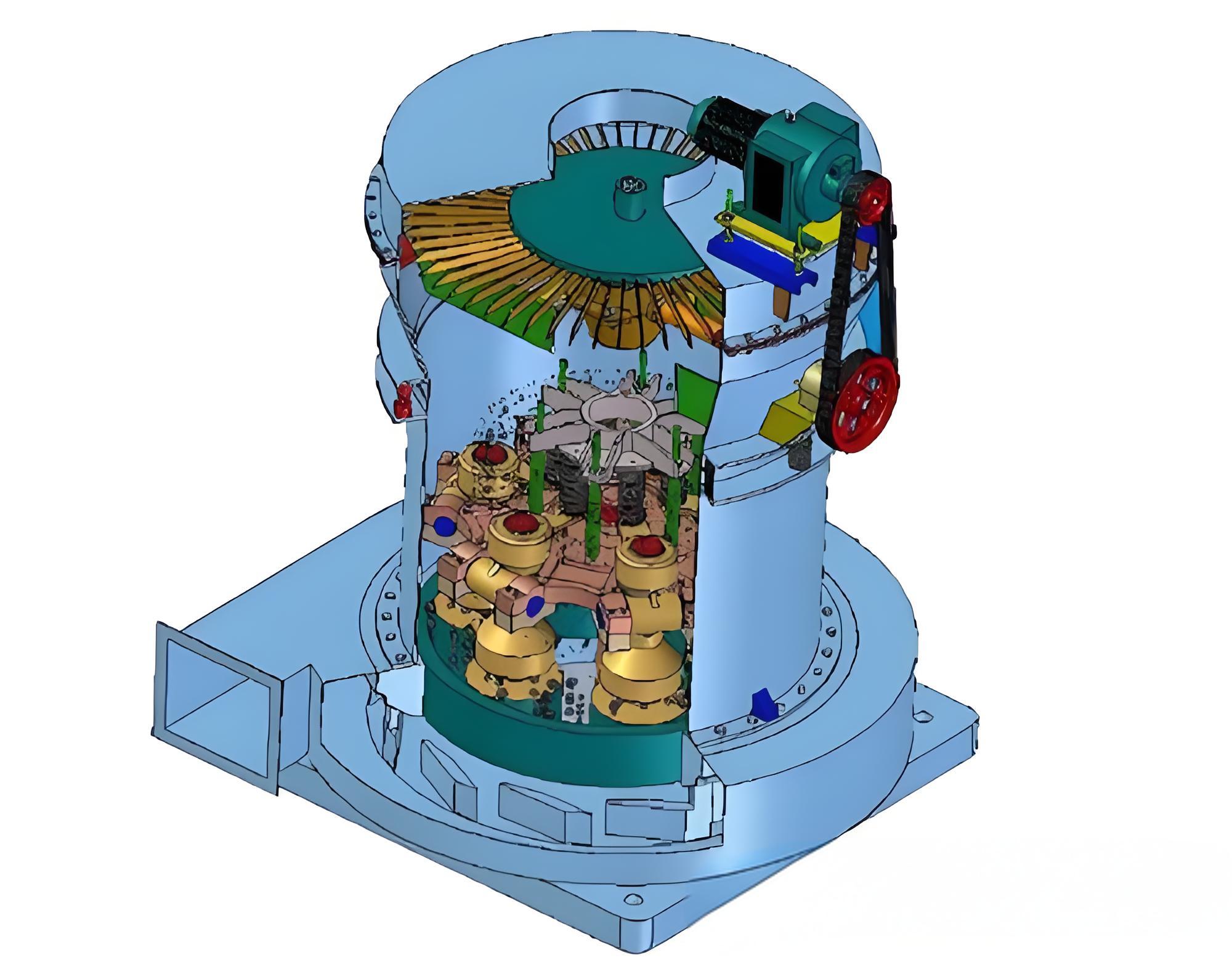

Raymond mill is a kind of grinding machine, mainly composed of main machine, reducer, analyzer, fan, bag dust collector, pipeline configuration, powder collector, motor, etc. The complete set of supporting equipment consists of jaw crusher, bucket elevator, feeder, silo, electric control cabinet, etc. It is mainly suitable for the grinding and processing of mineral materials such as mines in metallurgy, building materials, chemical industry and other industries, as well as various non-flammable and explosive mineral products with Mohs hardness below 9 and humidity below 10%.

1. Innovative roller, grinding ring and blade designs

2. Roller linkage supercharger.

3. Flexible connection

4.Efficient and practical, product fineness can beadjusted

5. Energy efficient centrifugal fan

6. The gap adjustment of the end of the separatorand the shell is more convenient and faster, whichimproved the efficiency of the powder collection

The working principle of Raymond mill is that the mill roll is tightly rolled on the mill ring under the action of centrifugal force, and the material is sent to the middle of the mill roll and the mill ring by the spatula. The material is broken into powder under the action of grinding pressure, and then the powder is blown up under the action of the fan and passes through the analysis machine. The material that meets the fineness requirement passes through the analysis machine, and the material that fails to meet the requirement returns to the grinding chamber to continue grinding. It is separated and collected by the cyclone separator of the analyser.

| Specifications | TGM100 | TGM130 | TGM160 | |

| Q ’ty of Rollers ( PCS) | 4 | 5 | 6 | |

| Inner Dia×Height of Roller (mm) | Φ310 × 170 | Φ410 × 210 | Φ440 × 270 | |

| Inner Dia×Height of Ring (mm) | Φ950 × 170 | Φ1280 × 210 | Φ1600 × 270 | |

| Main Mill Rotating Speed (r/min) | 130 | 98 | 82 | |

| Input Size (mm) | < 25 | <30 | <35 | |

| Output Size | μm | 1600-45, the finest 38 | ||

| Mesh | 10- 325, the finest 400 | |||

| Capacity (t/h) | 3 -8.8 | 6 - 15 | 9 -22 | |

| Overall Dimension (mm) | 6615 × 7725 × 8200 | 7000 × 9850 × 9695 | 9527 × 8003 × 9500 | |

| Weight (t) | 16 | 26.1 | 35 | |

| Motor of Main Mill | Model | Y225S-4 | Y280S-4 | Y315M1-4 | |

| Power (KW) | 37 | 75 | 132 | ||

| Rotating Speed ( r/ min) | 1480 | 1480 | 1480 | ||

| Motor of Separator | Model of Motor | YCT200-4A | YCT200-4B | YCT205-4A | |

| Power (KW) | 5.5 | 7.5 | 18.5 | ||

| Rotating Speed ( r/ min) | 125- 1250 | 125- 1250 | 125- 1250 | ||

| Motor of Blower | Model | Y225S-4 | Y280S-4 | Y315M1-4 | |

| Power (KW) | 37 | 75 | 132 | ||

| Rotating Speed ( r/ min) | 1480 | 1480 | 1480 | ||

| Jaw Crusher | Model | PE250X400 | PE250X400 | PE250 × 750 | |

| Model of Motor | Y180L-6 | Y180L-6 | Y200L2-6 | ||

| Power (KW) | 15 | 15 | 22 | ||

| Rotating Speed ( r/ min) | 970 | 970 | 970 | ||

| Auxiliary Parts | Bucket Elevator | Model of Elevator | TH220x8m | TH220x8. 5m | TH315x9m |

| Model of Motor | Y100L2-4 | Y100L2-4 | Y112M-4 | ||

| Power (KW) | 3 | 3 | 4 | ||

| Rotating Speed (r/ min) | 1420 | 1420 | 1420 | ||

| Feeder | Model of Motor | GZ2F | GZ2F | GZ3F | |

| Power (KW) | 0.15 | 0.15 | 0.2 | ||

Note: The above capacity is based on grinding calcite, and the technical data is subject to change without prior notice. The specific product is subject to the operation manual.

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.