Sand making is the process of processing raw materials like rocks and construction waste into qualified manufactured sand using machines. The sand making machine is the core equipment that accomplishes this task. Choosing the right sand making machine directly determines the efficiency and profitability of your project. This article provides a detailed analysis of the characteristics and applicable scenarios of five mainstream sand making machines to help you make a precise choice.

I. In-depth Analysis of Five Major Sand Making Machines

1. VSI Crusher (VSI Sand Maker): The Preferred Choice for High-Quality Sand and Aggregates

The VSI crusher (sand maker) is a high-efficiency sand making equipment that uses a high-speed rotating impeller to hurl materials, achieving crushing and shaping through the "rock-on-rock" or "rock-on-iron" principle.

Suitable Materials: Medium to high hardness and extremely hard, highly abrasive materials such as granite, river pebbles, basalt, andesite, etc. It is the preferred equipment for producing sand specifically for high-grade concrete and asphalt mixtures.

Feed Size: ≤50mm.

Capacity Range: 50-500 t/h.

Price Range: > $14,400 / set.

Advantages:

① VSI crushers produce rounded sand particles with extremely low flaky content, making them ideal aggregate for high-strength concrete and asphalt pavements.

② VSI crushers integrate crushing, shaping, and sand-making functions, simplifying the process.

③ The core wear-resistant components of VSI crushers are made of high-alloy materials, ensuring a long service life.

④ VSI crushers feature advanced sealing structures and optional dust collection designs, effectively controlling dust dispersion during production and meeting stringent environmental protection requirements.

Disadvantages:

① VSI crushers have strict requirements on feed particle size and require pre-crushing equipment;

② The unit price of VSI crushers is relatively high;

③ VSI crushers are prone to clogging when processing sticky materials; moisture content needs to be controlled.

Selection Considerations:

If you consider sand quality a core competitive advantage and the raw material has high hardness, then choosing an impact crusher is an investment to increase the market price of your product. If your finished sand mainly supplies key projects or commercial concrete plants, then a VSI crusher is undoubtedly the best choice

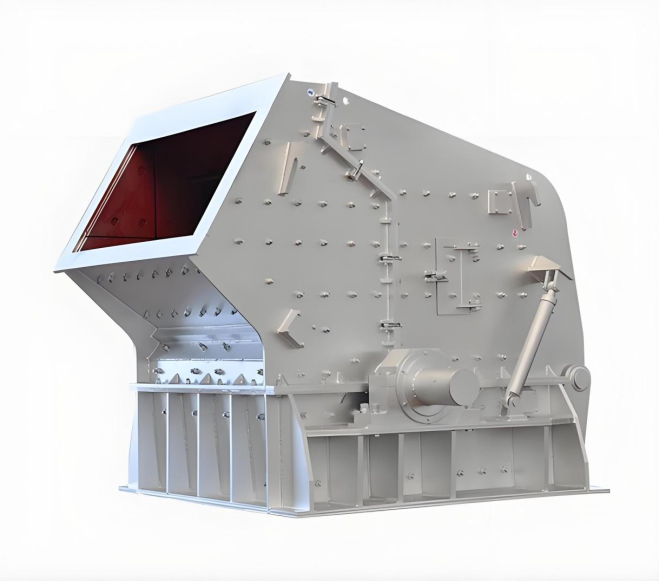

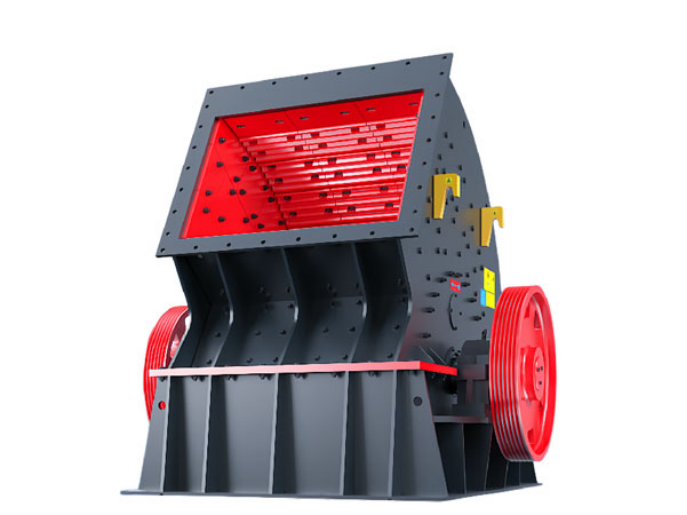

2. Impact Crusher (Secondary Impact Crusher): Optimal for Medium to Low Hardness Materials

The impact crusher is a multi-purpose impact crushing device that uses a high-speed rotating rotor driving hammers to impact materials, serving both medium/fine crushing and sand making functions.

Suitable Materials: Medium to low hardness, less abrasive materials such as limestone, recycled construction concrete, coal gangue, sandstone, etc. It plays a major role particularly in construction waste recycling and limestone sand production lines.

Feed Size: ≤500mm (can directly process medium-sized raw material blocks, offering wide applicability).

Capacity Range: 50-500 t/h, flexibly matching production lines of different scales.

Price Range: > $20,000 - $60,000.

Advantages:

① Impact crushers have a simple structure, are easy to install and debug, and have a short commissioning cycle.

② Impact crushers produce high-quality aggregates, suitable for aggregate production and sand making.

③ Compared to VSI crushers, impact crushers have lower equipment purchase costs, making them an ideal choice for projects with limited budgets or medium-sized projects.

④ Impact crushers can directly process large materials up to approximately 500mm in size, serving as the core equipment for secondary crushing and sand making.

Disadvantages:

Impact crushers are not suitable for crushing high-hardness, highly abrasive materials (such as granite and basalt) because the hammers and impact plates wear out extremely quickly.

Selection Considerations:

If your project's raw materials are suitable, and you need a single machine to simultaneously produce various sizes of crushed stone and manufactured sand to simplify the process and control total investment, it is recommended that you focus on evaluating impact crushers.

3.Hammer crusher: a powerful tool for making sand from brittle materials

A hammer crusher is a primary crushing equipment that relies on high-speed rotating hammers to impact materials and uses grate bars to control the discharge particle size.

Suitable materials: medium to soft materials such as quicklime, dolomite, gypsum, bricks, limestone, coal, and glass.

Feed size: ≤300mm

Capacity range: 50-600 tons/hour

Price range: Typically above $900

Advantages:

① Hammer crushers have low initial investment costs and low energy consumption, making them suitable for users with limited funds and low requirements for sand and gravel quality;

② Hammer crushers have a compact structure, small footprint, and are easy to install and operate, requiring no professional technicians;

③ Hammer crushers have a large crushing ratio, producing medium and fine sand in a single operation;

④ Hammer crushers can quickly produce finished sand when crushing soft materials;

Disadvantages:

① Hammer crusher hammers wear quickly and are highly sensitive to material hardness, making them unsuitable for processing high-hardness rocks;

② The finished product from a hammer crusher has poor particle shape and uneven gradation, only meeting the needs of ordinary construction sand;

Selection Points:

If your raw material characteristics perfectly match the crusher, your budget is extremely limited, and your requirements for the finished particle shape are "acceptable," then a hammer crusher can be considered an entry-level choice.

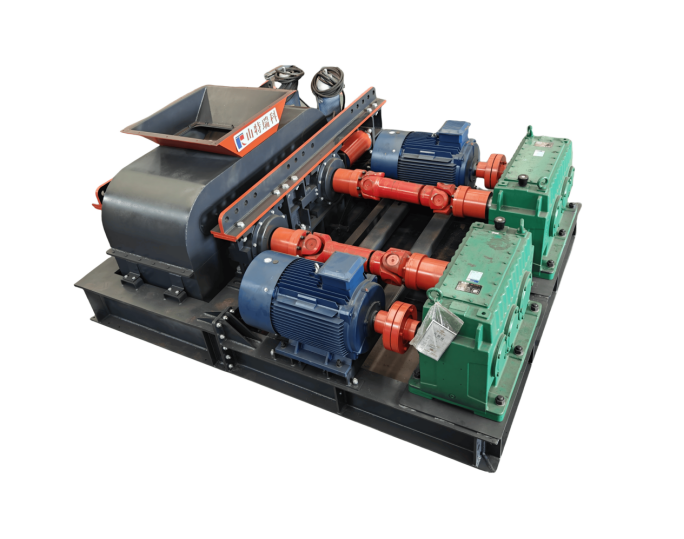

4. Double Roll Crusher: Environmentally Friendly, Adapted for Niche Scenarios

The double roll crusher is a fine crushing and sand making device that crushes materials through the squeezing and grinding action of two counter-rotating rolls, typically used for tertiary crushing in sand plants.

Suitable Materials: Particularly suitable for fine crushing and sand making of materials like pebbles, river stones, slag, coke, clay, etc., especially for sand production scenarios requiring control of stone powder content.

Feed Size: ≤30mm (requires uniform feeding and small particle size).

Capacity Range: 5-100 t/h.

Price Range: $3300 / set.

Advantages:

① Double roll crushers easily control the stone powder content in the finished product, making them particularly suitable for producing sand for dry-mixed mortar and special building materials with strict requirements for stone powder content.

② The finished product particle size of double roll crushers is uniform and controllable; the hydraulic automatic gap adjustment function can control the fine sand particle size within the range of 0-5mm.

③ Double roll crushers have strong tolerance to sticky materials such as clay, wet materials, and slag, and are not prone to clogging.

④ Double roll crushers operate with low noise, low vibration, good sealing, and low dust, fully meeting environmental protection requirements.

Disadvantages:

① The single-unit capacity of double roll crushers is relatively low, making them unsuitable for large-scale, high-output needs.

② Double roll crushers have a weaker ability to process high-hardness materials and are suitable for medium-to-low hardness and sticky materials.

Selection Recommendation:

If your primary need is to produce sand for dry-mixed mortar, or if you require strict control of the stone powder content in the finished product, then double roll crushers offer unique advantages.

5. Mobile Sand Making Machine (Mobile Crushing Plant)

A mobile sand maker refers to a complete mobile sand production line integrated onto one or more movable tire or crawler tracks, comprising feeding, crushing, sand making, screening, and conveying systems.

Suitable Materials: Mobile sand makers have strong adaptability and can operate directly on sites like quarries and construction sites, effectively crushing materials of various hardness from limestone and construction waste to granite and basalt.

Advantages:

① Mobile sand making machines are available in both tracked and wheeled drive systems, facilitating rapid movement and allowing the equipment to follow material sources or construction sites.

② Once the mobile sand making machine arrives on site, it can be installed and put into use within 30 minutes simply by connecting a power source.

③ Mobile sand making machines integrate intelligent control, one-button adjustment, and remote monitoring functions, making operation more convenient.

Disadvantages:

① The purchase cost of a single mobile sand making machine is significantly higher than that of a stationary sand making machine with the same capacity.

② Compared to stationary crushers, mobile sand making machines have limited capacity.

II. Scientific Selection Guide

1. Material Characteristics

For high-hardness materials (such as granite and basalt), choose a VSI crusher; for medium-to-low hardness materials (such as limestone and weathered rock), choose an impact crusher; for brittle materials (such as coal and shale), use a hammer crusher; for sticky and wet materials, prioritize a double-roll crusher. For wet materials, choose an anti-clogging model; large raw materials require pre-crushing equipment.

2. Capacity Matching

For capacities exceeding 100 tons/hour, choose a VSI impact crusher; for capacities between 50-100 tons/hour, choose an impact crusher (secondary crushing) or a vertical shaft impact crusher; for small sand making plants with capacities below 50 tons/hour, hammer crushers or double-roll crushers offer better cost-effectiveness.

3. Meets Finished Product Standards

For high-standard projects such as high-speed rail and bridges, VSI crushers are the preferred choice; for ordinary construction sand, impact crushers or hammer crushers can be selected; for fine crushing requirements of special fine sand, roller crushers can be used in conjunction.

4. Calculate Overall Costs

VSI crushers and mobile sand making machines have higher initial investment but significant long-term benefits; hammer crushers have lower costs but require frequent replacement of parts, leading to greater losses.

III. Conclusion: Let Choice Return to Production Reality

There is no "best" equipment, only the "most suitable" solution. If you are still unsure how to choose, we recommend:

Providing a 30-50kg raw material sample for a free crushing test;

Inviting technical personnel for an on-site inspection to customize a plan for you;

Visiting operational production lines of the same type to witness equipment performance firsthand.

Choosing a sand making machine is choosing the production efficiency for the next 5-10 years. We are committed to helping you embark on a path of stable profitability with professional equipment and sincere service—starting from the first ton of high-quality manufactured sand.