The impact crusher is widely used for crushing and shaping soft, medium hard, and extremely hard materials, and is widely used for fine crushing of various mechanical construction sand and gravel materials such as ores, cement, refractory materials, and diamond sand, as well as various metallurgical slag. Especially for high hard, extra hard, and corrosion-resistant materials such as silicon carbide and diamond sand, it has higher production efficiency than other types of crushers.

Performance characteristics:

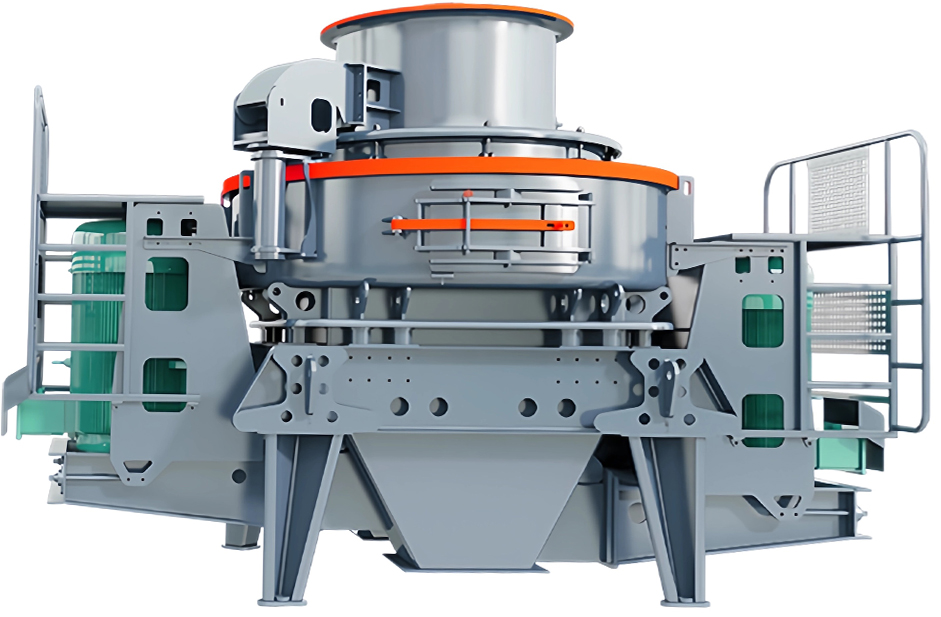

1. The structure is simple and consists of a feeding hopper, a separation hanger, a vortex crushing chamber, an impeller, a main shaft assembly, a base, a transmission device, and a motor.

2. Efficient and energy-saving, high crushing efficiency, optimized deep cavity rotor, improved material passing rate, and improved crushing efficiency.

3. Thin oil lubrication, integrated with air cooling and cooling, dual oil pumps complement each other to ensure oil supply, automatic shutdown when there is no oil flow or oil pressure, adopting air cooling for excellent cooling effect. The motor is heated and started in winter, reducing the labor intensity of workers and ensuring that bearing lubrication is always in the best state, extending the service life of the equipment.

4. The core wear-resistant material adopts highly wear-resistant and high-temperature resistant materials.

5. The equipment has strong processing ability, with the optimal launch port and smooth curve design inside, reducing the flow resistance of materials and significantly improving the equipment's processing capacity.

6. Dual purpose loose material tray, easy to operate, achieving rapid conversion between two feeding methods.

7. Low work noise, low dust pollution, using well-known brand high protection level motors, high efficiency, and low noise. Complies with IEC standards.