What Stones Are Suitable for Jaw Crusher Machine

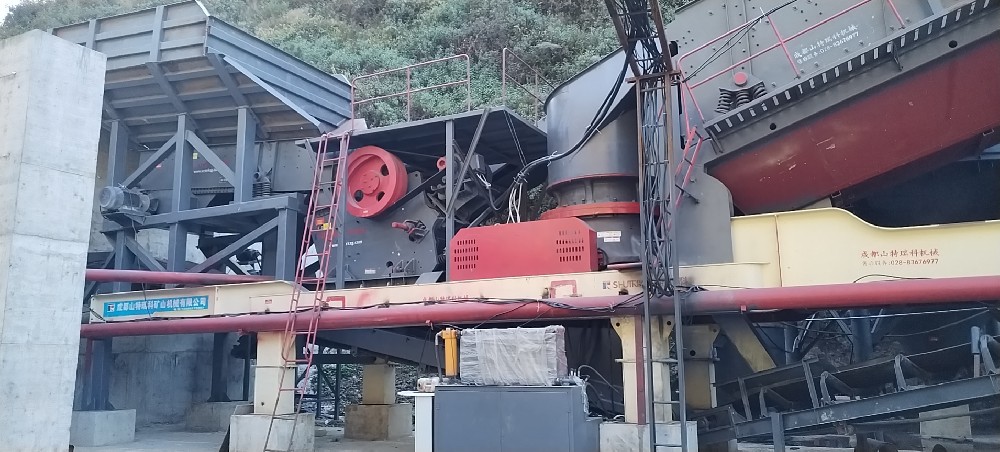

In the mining and construction industries, selecting the right stone crusher machine is crucial for efficient material processing. Among the various types of stone crushers, the jaw crusher machine stands out due to its robustness and versatility. This article delves into the jaw crusher uses and explores what types of stones are best suited for this type of machinery.

Jaw Crusher Uses

A jaw crusher machine, also known as a jaw breaker, operates through a crushing chamber where materials are compressed between a fixed jaw and a moving jaw. The moving jaw is powered by an electric motor that drives a belt and pulley system, causing the eccentric shaft to move the jaw up and down. When the moving jaw rises, the angle between the jaw and the toggle plate increases, pushing the jaw plate closer to the fixed jaw plate and crushing the material. As the jaw descends, the angle decreases, and the jaw plate moves away from the fixed jaw plate, allowing the crushed material to exit the chamber. This cyclic motion allows the jaw crusher to process large volumes of material efficiently.

Types of Stones Suitable for Jaw Crushers

The jaw crusher machine is designed to handle a wide range of stones, making it a versatile option for various industries. Here are some of the stones commonly crushed using jaw crushers:

Construction Aggregates: Stones like granite, basalt, river gravel, limestone, quartz, iron ore, and bluestone are widely used in the construction industry. These stones are crushed into different sizes to produce aggregates for concrete, asphalt, and other building materials.

Mining Ores: Minerals such as sulfur iron ore, phosphate rock, baryte, and celestine often require crushing before further processing. The jaw crusher's high crushing ratio and adjustable outlet size make it ideal for preparing mining ores for transportation and refining.

Industrial Materials: In addition to natural stones, jaw crushers can also handle industrial waste and by-products, such as metallurgical slag and refractory materials. These materials are crushed for recycling or disposal.

Advantages of Using Jaw Crushers

High Crushing Ratio: Jaw crushers can reduce large rocks to smaller sizes efficiently.

Uniform Particle Size: The adjustable outlet allows for precise control over the particle size of the crushed material.

Durability: Constructed from heavy-duty materials, jaw crushers are built to withstand the wear and tear of continuous use.

Versatility: Suitable for a wide range of materials, making it a versatile option for different industries.

Stone Crusher Machines in General

While jaw crushers are a popular choice, there are several other types of mobile crushing plant available, including cone crushers, impact crushers, hammer crushers, and roller crushers. Each type has its unique features and is suited for specific applications. Choosing the right machine depends on the material being crushed, the desired particle size, and the production capacity required.

Conclusion

In summary, the jaw crusher machine is a versatile and efficient tool for crushing a wide range of stones and materials. Its robust design and adjustable outlet make it suitable for various industries, from construction to mining. By understanding the jaw crusher uses and selecting the right stones for processing, businesses can optimize their material handling processes and achieve higher productivity.