jaw crusher machine/jaw crusher components/jaw crusher uses/jaw crusher repair

The jaw crusher machine is a key machine in the mining, construction, and aggregate industries. It is designed to break large pieces of rock into smaller, more manageable pieces, making it an essential tool for a variety of applications. This article takes an in-depth look at the jaw crusher components, jaw crusher uses, and the jaw crusher repair to gain a comprehensive understanding of its functions and importance.

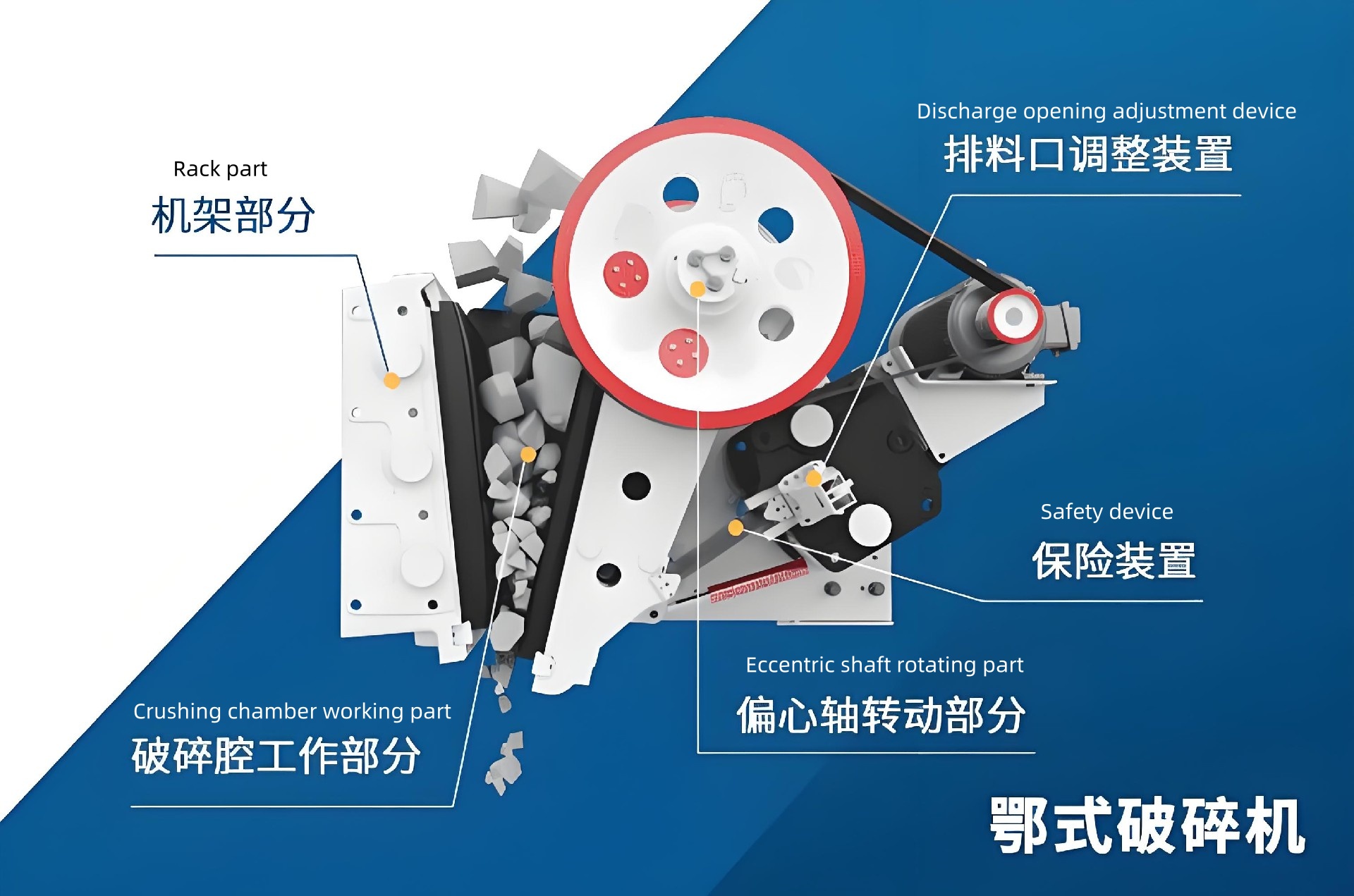

Jaw Crusher Components

A jaw crusher consists of several key components that work together to perform its functions. The main components include:

Crushing Chamber: This is where the actual crushing takes place. It consists of two jaws, one fixed and the other moving, which compress the material to break it down.

Fixed Jaw: Mounted on the frame of the crushing plant, the fixed jaw remains stationary during the crushing process.

Moving Jaw: The moving jaw is connected to a rotating eccentric shaft, which applies pressure to the fixed jaw.

Switch Plate: This component acts as a safety device and helps transmit the crushing force. It also allows the jaw to move in a controlled manner.

Eccentric Shaft: This is the main drive shaft of the crusher plant and is responsible for the movement of the moving jaw.

Bearings and support seats: These components ensure smooth operation of the eccentric shaft and moving jaw.

Side plates: These are protective linings that prevent wear on the crusher frame.

Uses of jaw crushers

Jaw crushers are versatile machines used in a variety of industries. Their primary function is to crush hard materials, making them indispensable in the following sectors:

Mining: Jaw crushers are used to break down ore into smaller fragments for further processing.

Construction: They are used to crush concrete and other construction waste for recycling.

Quarrying: Jaw crushers help break down large rocks into smaller aggregates for use in construction projects.

Demolition: These machines are used to process demolition waste, separating valuable materials from the debris.

Asphalt production: Jaw crushers are used to crush asphalt for road construction and maintenance.

Jaw crusher repairs

Regular maintenance and timely repairs are essential to ensure the life and efficiency of your jaw crusher. Here are some important maintenance tips:

Regular inspections: Perform routine inspections of all components, including jaws, toggle plates, and bearings to identify any signs of wear or damage.

Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and prevent overheating.

Replacement of worn parts: Replace worn or damaged parts promptly to avoid further damage to the machine.

Alignment checks: Regularly check the alignment of the jaws and eccentric shaft to ensure optimal performance.

Cleaning: Keep the crushing plant clean and free of debris to prevent clogging and ensure smooth operation.

Training: Ensure that the operator is well trained in the use and maintenance of the jaw crusher to prevent accidents and equipment damage.

Conclusion

Jaw crushers are essential machines in various industries, providing essential services in material reduction and processing. Understanding the components, uses, and maintenance requirements of a jaw crusher is essential to maximizing its efficiency and lifespan. By adhering to a regular maintenance schedule and addressing any issues promptly, operators can ensure that the jaw crusher remains in optimal working condition, which helps to complete the job successfully.