Processing hard rocks such as granite, basalt, and quartzite is a challenge for many aggregate quarries. They often struggle with poor aggregate shape and high fines content due to improper crushing methods, resulting in lower prices and reduced profits.

This article will explain in detail how to transform hard rocks into high-quality aggregate, helping you earn more money.

Crushing and Refining

To obtain high-quality aggregate from mined boulders, three stages of processing are required: primary crushing, secondary crushing, and fine crushing.

Primary Crushing (Coarse Crushing): Large pieces of raw ore (500-1000mm in diameter) are fed into a jaw crusher and crushed into 100-300mm chunks.

Jaw crushers work by the coordinated squeezing motion of a movable jaw and a fixed jaw.

When choosing a jaw crusher, select one with high-manganese steel jaw plates. This will help you reliably process high-hardness rocks, providing reliable protection for the entire process and saving on operating costs.

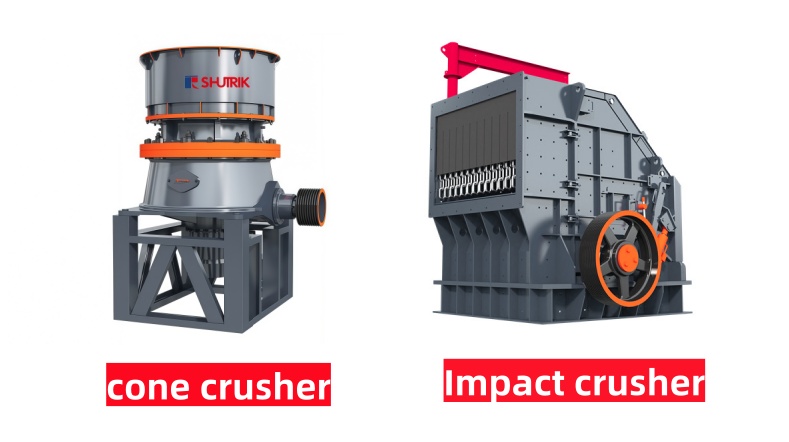

Secondary Crushing (Medium and Fine Crushing): The crushed stone from the primary crushing stage is fed into a cone crusher or impact crusher, reducing the particle size to 20-50mm.

For high-hardness, highly abrasive hard rocks (such as granite and basalt), we usually recommend using a cone crusher.

Cone crushers utilize the principle of layered crushing, which not only achieves efficient crushing but also significantly optimizes the aggregate shape, resulting in less wear and more stable operation. If you are pursuing higher long-term output, lower overall losses, and high-quality aggregate, a high-performance cone crusher is undoubtedly your core guarantee.

When processing medium-to-low hardness hard rocks (such as limestone) or brittle rocks (such as slate), an impact crusher is recommended. Its impact crushing principle produces aggregate with a rounder shape and lower needle-like and flaky content, making it particularly suitable for road construction and high-standard concrete production where both appearance and strength are important.

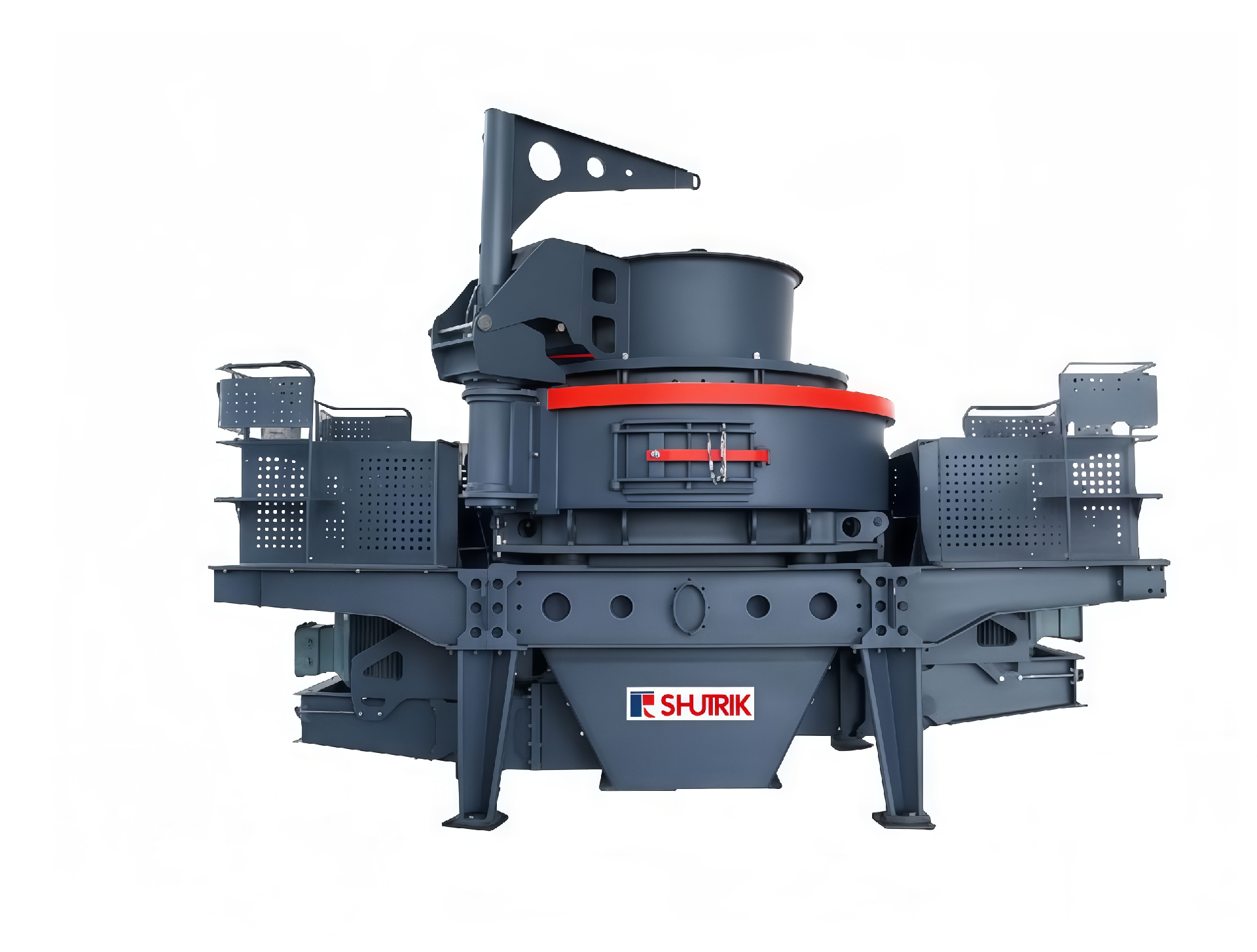

Finally, the material is finely crushed using a sand making machine or impact crusher to produce fine particles of 5-20mm, suitable for mainstream applications such as construction aggregate. Some industrial applications require further crushing to even finer particle sizes. Sand Making and Shaping (Fine Crushing): If you require high-value manufactured sand, you will need to further crush the ≤50mm aggregate material to 0-20mm using a sand making machine or impact crusher.

It uses the "stone-on-stone" or "stone-on-iron" principle to crush and shape the material, ultimately producing high-quality manufactured sand with rounded particle shapes and reasonable gradation, perfectly replacing natural sand.

If your goal is to produce high-quality manufactured sand for high-standard concrete, a high-efficiency sand making machine can significantly increase the value of your product.

Screening (Precise Classification): During the crushing process, vibrating screens play a crucial role in classifying and screening the products at each stage. Unqualified particles are returned to the corresponding crushing stage for secondary processing, forming a closed-loop production system. To ensure accurate screening, the vibrating screen should be selected based on the finished product requirements.

Sand Washing: Sand washing equipment effectively removes impurities and excess stone powder, ensuring clean aggregate. We recommend configuring a high-efficiency and durable washing system, which will ensure your final product meets the stringent requirements of various high-end applications.

If your hard rock needs to be processed into powder, you will need to add grinding equipment such as ball mills, Raymond mills, and vertical mills.

Applications of Hard Rock Aggregate

Processed hard rock has a wide range of applications and can bring you significant economic benefits.

1. Infrastructure Construction: High-Quality Aggregate and Manufactured Sand

This is the largest and most important application area for processed hard rock.

High-Grade Highways and Railways:Hard rock is used for subgrade paving, and high-quality aggregate is used for asphalt concrete pavements.

High-performance concrete: High-quality hard rock manufactured sand and various grades of crushed stone are essential raw materials for C30 commercial concrete.

Port and water conservancy projects: Large-particle, impact-resistant hard rock aggregate is specifically used for breakwaters, dams, and other heavy structures.

2. Building Foundation: Diversified Building Materials and Decoration

Hard rock processing can extend to a variety of building materials to meet different construction needs. Pre-mixed mortar and dry-mix mortar: High-quality manufactured sand is the foundation for producing high-quality mortar.

Precast components: From pipe piles to prefabricated building components.

3. Industrial raw materials: High-value-added fillers and products

Industrial fillers: Ground stone powder can be used as a filler for paints, plastics, and rubber.

Artificial stone and environmentally friendly bricks: Using stone powder and stone chips, it is possible to produce green building materials such as artificial quartz stone and permeable bricks.

Special applications: Specific hard rocks can be used as refractory materials, filter media, or abrasives.

Summary:

From solid rock to diversified high-value sand and aggregate, every critical link—whether it's the reliable primary crushing of jaw crushers, the efficient secondary crushing of cone crushers, or the fine shaping of sand making machines—relies on professional and reliable equipment as a solid foundation.

The right start is half the battle. If you are planning or upgrading a hard rock processing project and facing complex processes and equipment selection, we are willing to be your most trusted partner.

- Prev: How Does a Jaw Crusher Work?

- Next: 没有了!