-

75 +Global Cooperation Countries

-

1000 +Global Cooperative Customers

-

30000 setsWorldwide Sales Of Equipment

-

150 +Regional Distributor

Your current location:Home>Product>Stone Crushing Machine

Direct deal Quality Assurance Quick response Service worry free

Production capacity:15-800t/h

Feed particle size:Mainly used in metallurgy, chemical industry, hydropower engineering and other industries.

Applicable materials:Side length of 100 ~ 600 mm below the material, compressive strength up to 350 mpa. Limestone, coal gangue, river pebbles, granite, iron ore, etc.

![]() Do you need help? WhatsApp: +8613699023026

Do you need help? WhatsApp: +8613699023026

crusher@strkmac.com Hotline:+8613666220166

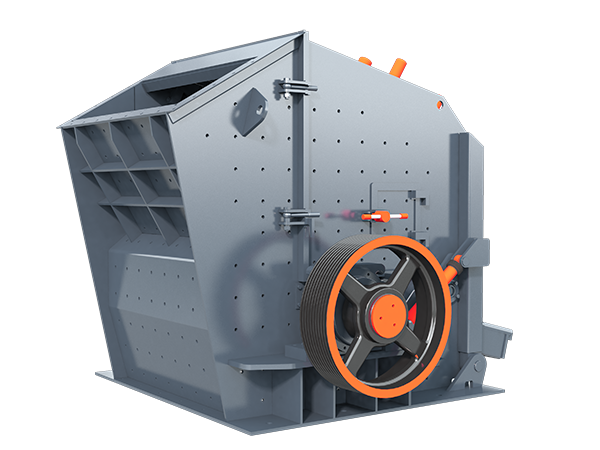

The impact crusher adopts new manufacturing technology and unique structural design, so that the finished product particles are cubic, no tension and cracks, and the shape is better. The equipment can crush all kinds of coarse, medium and fine materials (such as granite, limestone, concrete aggregate, etc.) with feed particle size no more than 800mm and compressive strength no more than 350Mpa.

1.Big crushing ratio, high crushing efficiency, cubic shape production.

2.The gap between plate hammer and impact hammer can be adjusted, and the discharging size can be controlled effectively.

3.The high chrome hammer is wearable.

4.Simple structure, and it is mainly including frame, rotor, and impact plate. The frame can be opened quickly by jack device in order to change spare parts and maintain.

5.The rotor and main shaft is connected by the Clamping Sets, which is easy for maintenance.

Impact crusher is a kind of crushing machine which uses impact energy to crush materials. When working, driven by the motor, the rotor rotates at a high speed. When the material enters the action area of the plate hammer, it collides with the plate hammer on the rotor, and then it is thrown to the impact device for crushing again. Then, it bounces back from the impact lining plate to the plate hammer action area for re crushing. This process is repeated, and the materials enter the first, second, third and impact cavities from large to small for repeated crushing until the materials It is crushed to the required size and discharged from the discharge port. Adjusting the gap between the impact frame and the rotor can change the size and shape of the material。

Model | specification | Feed size | Maximum feed | Processing capacity | Motor power | Overall dimension |

PF-1214 | ∅1250x1400 | 400x1430 | 300 | 90-120 | 132-160 | 2850*2400x2900 |

PF-1315 | ∅1320x1500 | 860x1520 | 350 | 120-150 | 180-220 | 3100x2800x3160 |

PF-1320 | ∅1300x2000 | 900x2030 | 500 | 160-350 | 260-300 | 3320x3218x2613 |

PF-1520 | ∅1502x2000 | 1315x2040 | 700 | 350-450 | 400-500 | 4138*3422x3649 |

PF-1820 | ∅1800*2000 | 1620x2040 | 900 | 550-800 | 630-710 | 4471*3250x4008 |

Thank you for your interest in Sandreck Mining Machinery(Zimbabwe) Co., Ltd.. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!

Sandreck Mining Machinery(Zimbabwe) Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, EPC general contract project and other professional high-end equipment manufacturing enterprises.